Table of Contents

Carving machine for wood safety

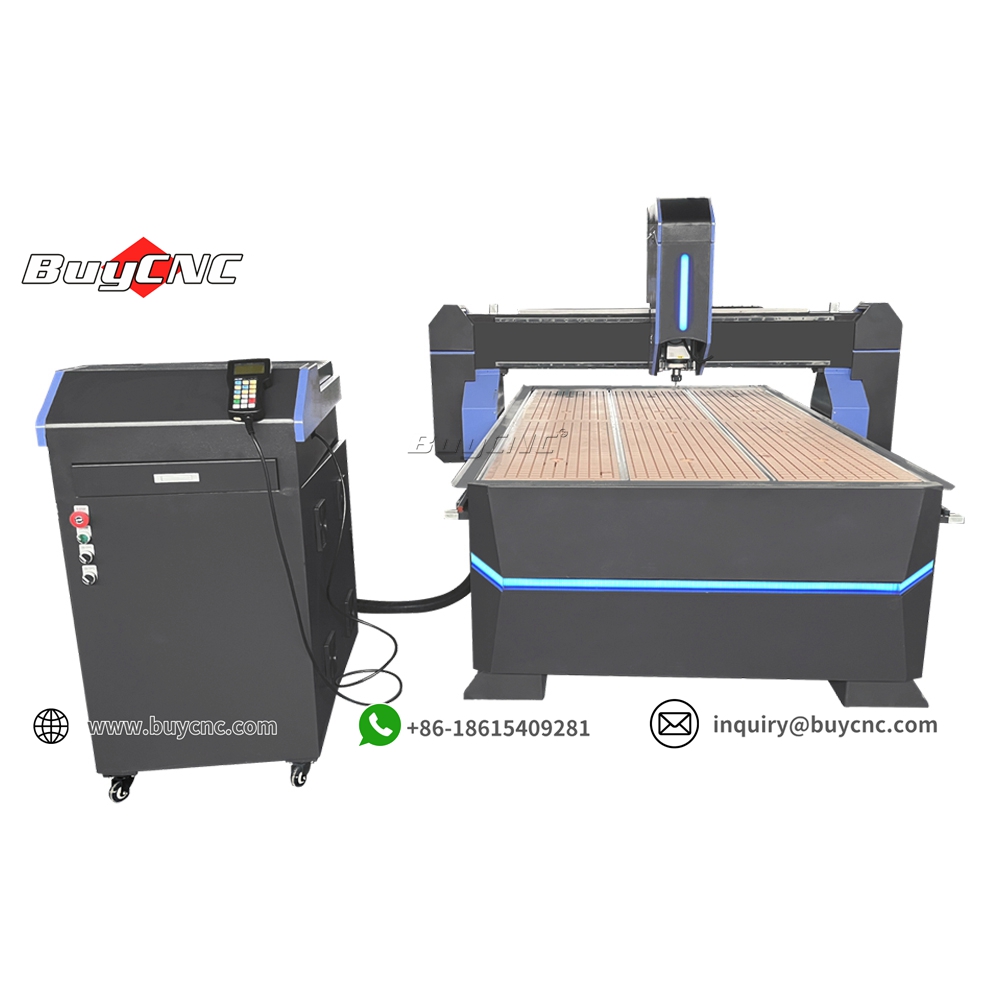

As a professional processing equipment, the safety of carving machine for wood is crucial. In order to ensure the safety of wood cnc machines and the safety of operators, manufacturers usually follow a series of relevant safety standards and regulations to design and produce these machines.

First of all,carving machines for wood must comply with relevant national and regional safety standards and regulations. These standards may include mechanical safety standards, electrical safety standards, and noise and vibration control standards, among others. Manufacturers must ensure that machines are designed, manufactured and used in compliance with these standards to ensure machine safety and stability.

Secondly, the requirements of ergonomics and operational safety will also be taken into consideration during the design and manufacturing process of carving machines for wood. For example, the machine’s operating interface should be simple, clear and easy to operate; the emergency stop button should be set in a conspicuous and easy-to-reach position; the machine’s shell and guard should be able to prevent operators from contacting dangerous parts, etc.

In addition,carving machines for wood will be equipped with various safety devices and protection measures to reduce potential safety risks. For example, the machine may be equipped with electrical protection devices such as overload protection and overheating protection; the spindle and cutting tools may be equipped with protective covers and protective nets; the machine may also be equipped with safety interlocking devices to ensure that the machine can automatically stop running under certain conditions.

At the same time, the manufacturer will also provide detailed safety operating procedures and instructions to ensure that operators can use the carving machine for wood correctly and safely. These procedures and instructions may include machine start-up and shutdown procedures, tool replacement and maintenance procedures, emergency response measures, etc.

It should be noted that even if the machine meets the standards, correct operation and maintenance by the operator are important factors in ensuring safety. Therefore, operators should strictly abide by operating procedures and conduct regular safety inspections and maintenance.

Carving machine for wood operation conditions and maintenance

First of all, the noise generated by the carving machine for wood during operation mainly comes from the motor, spindle and transmission system. To reduce noise, a range of measures can be taken. For example, choose low-noise motors, optimize the design of the spindle and transmission system, and perform regular machine maintenance and cleaning. In addition, placing shock-isolating materials on the bottom of the machine or using shock-absorbing devices can also effectively reduce machine vibration, thereby reducing noise pollution. In terms of the working environment, equipment such as noise-cancelling earplugs can be used to protect workers’ ears, or the machine can be placed in a specially soundproof room for processing.

Secondly, the carving machine for wood will produce a certain amount of dust during operation. In order to control dust pollution, machines are usually equipped with dust suction devices to reduce the dust content in the air through efficient dust suction. In addition, regular cleaning and maintenance of the machine to keep the machine clean can also effectively reduce the generation and accumulation of dust.

In terms of maintenance, whether a carving machine for wood is easy to maintain mainly depends on its design quality and manufacturing process. High-quality wood cnc machines usually have the characteristics of simple structure, easy disassembly of parts, and easy maintenance. In daily use, various parts of the machine, such as bearings, transmission belts, motors, etc., should be checked regularly to ensure that they are in good condition. Seriously worn or damaged parts should be replaced in time to ensure the normal operation of the machine.

As for whether parts need to be replaced regularly, this mainly depends on the service life and wear of the parts. Some wearing parts, such as cutting tools, transmission belts, etc., may need to be replaced regularly. As for core components such as spindles and motors, if they are of excellent quality and properly maintained, they usually have a long service life and do not need to be replaced frequently.

In general, the noise and dust control of carving machines for wood, as well as the ease of maintenance and whether parts need to be replaced regularly, are closely related to the design, manufacturing quality and use and maintenance of the machine. In order to ensure the stable operation of the machine and extend its service life, users should choose products with reliable quality and use and maintain them in strict accordance with operating procedures. At the same time, paying attention to the operating status of the machine, discovering problems in time and handling them are also the keys to ensuring stable machine performance.