lightweld 1500 laser welder

Video

Introduction of Laser Welder Machine

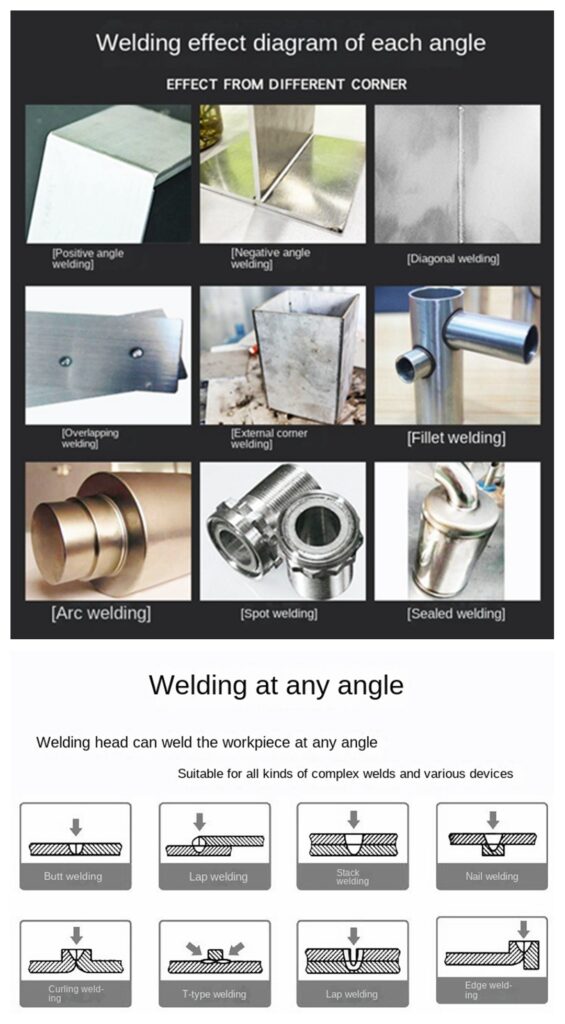

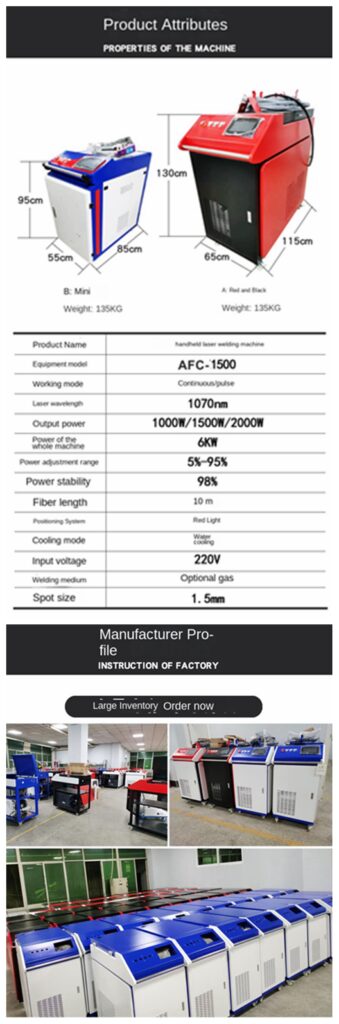

The welding seam of lightweld 1500 laser welder is beautiful, fast, no consumables, no welding marks, no discoloration, and no need to polish later. Various angle nozzles can be configured to meet the welding needs of different products.

lightweld 1500 laser welding machine is a kind of laser welding equipment that couples high-energy laser beams into optical fibers, collimates them into parallel beams through a collimating mirror after long-distance transmission, and then focuses them on the workpiece and the weld. Soft-transmit non-contact welding for hard-to-reach areas for greater flexibility. The laser beam can realize time spectrum and energy spectrum, and simultaneously perform multi-beam processing, which provides conditions for more precise welding.

Advantages of Lightweld 1500 Laser Welder:

1. Safer and more environmentally friendly.

2. One machine can save at least 2 welders a year.

3. Fewer consumables for laser welding and long service life.

4. The laser welding workpiece has no deformation, and the welding is firm.

5. Laser welding speed is 2-10 times faster than traditional welding.

6. The welding seam is flat and beautiful, reducing the subsequent grinding process, saving time and cost.

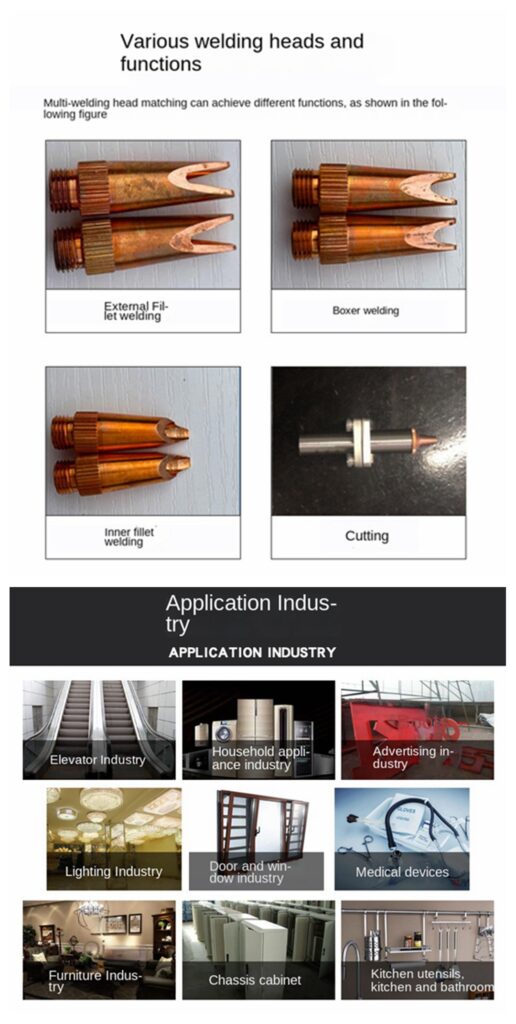

7. Independent research and development of welding heads to make up for the shortcomings of small laser welding spots, expand the tolerance range and weld width of processed parts, and obtain better weld formation.

Applications of Aluminum Laser Welding Machine:

1. Building materials industry

The precision of lightweld 1500 laser welder has a good appearance, so it has a wide range of applications in laser marking and laser welding of high-end sanitary stainless steel products. Such as: handles, faucets, stainless steel tableware, knives, etc., laser marking is often used to make corporate LOGO, and the sealing of high-end electric kettles is also completed by laser welding.

2. Kitchenware industry

In the kitchenware industry, a large number of sheet metal parts need to be welded. For example: group welding and butt welding of kitchen utensils, repair and modification during mold making and use. Laser welding perfectly solves the two major problems of weld beauty and welding quality.

3.Lighting industry

In the lighting industry, due to the complexity of the shape and structure of the lighting, there are many hard-to-reach parts that cannot be welded by ordinary welding machines, and the effect after welding must be guaranteed. The lightweld 1500 laser welding machine has exactly this function. The welding angle can be moved at will to achieve better welding effect and break the space limitation of traditional welding.

4. Mould and machinery manufacturing

The most typical example of the application of Lightweld 1500 laser welder machine in the mold industry is the mold repair laser welding machine. Due to the obvious advantages of non-contact processing, laser processing is especially suitable for molds and high-precision machinery manufacturing industries, such as plastic molds, rubber molds, stamping molds, casting molds, etc. , Forging dies, precision repair of wire drawing dies.

This laser welding repair technology can not only be used to repair mold wear, but also achieve precise welding of small and precise areas without deformation and pores after repair.

FAQ

Q1. How to choose the right lightweld 1500 laser welder?

Just tell us the material and its thickness, and we have professional managers to recommend the best machine for you.

Q2. I bought a lightweld 1500 handheld laser welding machine and don’t know how to operate it?

We come with detailed installation and operating instructions. It’s super easy and we also offer 24 hour phone and email support. Our engineers can also provide mechanical services overseas, but not for free.

Q3. What should we do if there is a problem with the lightweld 1500 laser welding system?

24 hours timely response by email and phone or engineer overseas service, but not free.

Q4. Can I change the input voltage to my local voltage and frequency?

Yes, we can supply frequency and voltage according to your local standard. Such as 220V/380V/415V/440V/480V 3-phase.

Want to Get the Laser Welder Machine Price?Get Free Consultation Now!!!

Reviews

There are no reviews yet.