Table of Contents

In the stone processing industry, stone carving routers are indispensable key equipment on the production line. With the growing demand for stone processing, improving the durability and extending the service life of stone carving routers has become an important strategy for enterprises to reduce costs and improve efficiency. The following will explore how to enhance the durability of stone carving routers through a series of measures.

Choose a high-quality stone carving router

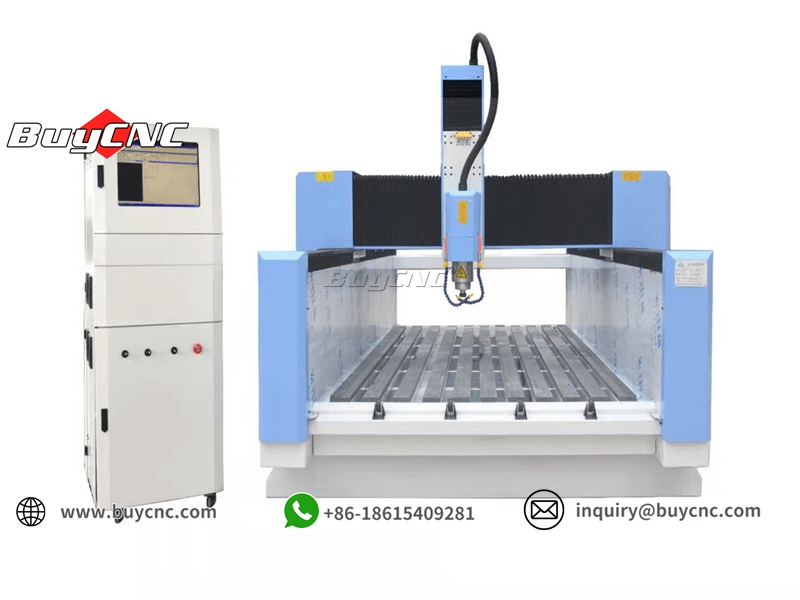

The first step to improve the durability of your stone carving router is to purchase high-quality equipment. When purchasing, you should pay attention to the manufacturing materials, process and structural design of the equipment. High-quality manufacturing materials and fine craftsmanship can ensure that the equipment is more stable and wear-resistant during operation, reducing the possibility of failure. At the same time, reasonable structural design can reduce the vibration and noise of the equipment and improve the operating efficiency of the equipment.

Strengthen the daily maintenance and maintenance of stone carving routers

Routine maintenance and upkeep of equipment is the key to extending its service life. stone carving routers should be lubricated, tightened, cleaned and inspected regularly. Lubrication can reduce the wear of equipment parts, fastening can ensure the stability of the equipment, cleaning can prevent the accumulation of dust and debris inside the equipment, and inspection can detect and deal with potential problems in time. In addition, reasonable maintenance plans and cycles should be formulated based on the actual operation of the equipment.

Reasonable use of stone carving routers

How the stone carving router is used can also affect its durability. During use, overloading, overspeeding and long-term continuous operation should be avoided. Overloading and overspeeding will increase the load on the equipment and accelerate the wear and aging of parts; long-term continuous operation will overheat the equipment and reduce its performance and life. Therefore, working hours and loads should be reasonably arranged according to the performance and production needs of the equipment.

stone carving router technology upgrade and transformation

With the advancement of science and technology, the technology of stone carving routers is also constantly updated. Through technological upgrading and transformation, equipment performance can be improved, energy consumption reduced, and failure rates reduced, thus extending its service life. For example, the use of advanced control systems and sensor technologies can realize intelligent operation and fault diagnosis of equipment; the use of new materials and processes can improve the wear resistance and corrosion resistance of equipment.

Strengthen employee training and stone carving router management

Employees are the main body of equipment operation and maintenance. Strengthening employee training and management can improve employees’ professional skills and safety awareness and reduce the impact of human factors on equipment. Enterprises should establish a complete training and management system and provide regular skills training and safety education to employees to ensure that employees are proficient in the operation methods and maintenance requirements of the equipment.

Establish stone carving router files and maintenance records

Establishing equipment files and maintenance records can help enterprises understand the operating status and maintenance history of equipment, and provide data support for equipment maintenance and upkeep. By regularly analyzing equipment operating data and maintenance records, potential equipment problems can be discovered in a timely manner and targeted maintenance and upkeep plans can be formulated.

To sum up, improving the durability of stone carving routers and extending their service life requires starting from many aspects. The durability of stone carving routers can be significantly improved through the comprehensive use of measures such as purchasing high-quality equipment, strengthening daily maintenance and upkeep, using equipment rationally, carrying out technical upgrades and transformations, strengthening employee training and management, and establishing equipment files and maintenance records. and extend its service life to create greater value for the enterprise.