Table of Contents

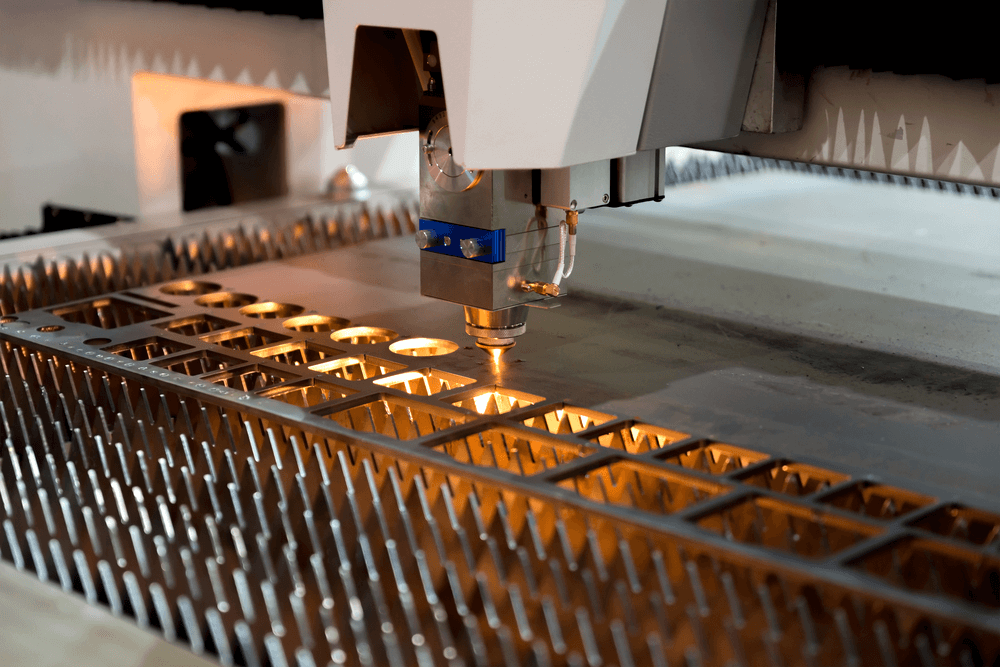

A laser cutting machine is a device used to process metal materials. The price is often not low, ranging from a few thousand dollars to tens of thousands of dollars. Because most of these expensive machines are used to process metal materials, the only way to save production costs is to prolong the service life of the laser cutting machine as much as possible. So how to maintain the laser cutting machine in daily work? How to prolong the service life of laser cutting machine?

Before understanding the daily maintenance of the laser cutting machine, we need to understand the main components of the laser cutting machine, which are mainly divided into: circuit system, transmission system, cooling system, light source system, and dust removal system. The main parts that need to be maintained are the cooling system (to ensure the constant temperature effect), the dust removal system (to ensure the dust removal effect), the optical path system (to ensure the quality of the beam), and the transmission system (the focus needs to be paid attention to to ensure normal operation). In addition, a good working environment and correct operating habits are also beneficial to prolong the service life of the laser cutting machine.

How To Properly Maintain The Laser Cutting Machine?

The application of laser cutting machine in our life can be said to be very extensive, and it can indeed bring us a lot of advantages in use. In the process of using it, everyone must be able to operate it correctly, so that the machine can be better extended. It has a long service life and can avoid failures in the process of operation and use, so let’s give you a comprehensive introduction, how can we properly maintain and maintain the laser cutting machine?

In the process of using the laser cutting machine, everyone must be able to operate correctly, and must be able to conduct a comprehensive inspection before use, and the operating staff must be able to understand the rules and regulations of the operation, and must be able to reasonably To use it, you also need to be able to operate correctly, but if you find any faults or something wrong when using it, you must be able to shut down and stop in time, and then you can work normally after inspection.

It must be able to be cleaned regularly after a period of use. The main purpose of cleaning is to be able to carry out a comprehensive overhaul. After all, after a period of use, many parts will definitely wear out, and there will also be some small faults, so by doing this The maintenance and repair can avoid small failures into major failures, and the maintenance process is also very simple, and it can also avoid more costs during maintenance.

Therefore, in order to properly maintain the laser cutting machine, and to extend the overall service life, it is necessary to be able to carry out maintenance through professional and formal methods, and also to be able to perform correct operations. When there is any problem, you must be able to check it in time, and do not let the machine work while sick.

How To Maintain The Fiber Laser Cutting Machine During Work

The fiber laser cutting machine itself is a kind of precision instrument. In the process of use, it must be properly maintained and maintained. Of course, how should this machine be maintained? In fact, there is still a lot of professional knowledge, because only by mastering this professional knowledge can we better play the relevant equipment functions and improve the working efficiency of related equipment to the greatest extent.

In the process of using the fiber laser cutting machine, the steel belt must be checked frequently, and the tension state of the steel belt must be ensured. Otherwise, there will be many problems during the operation, and it may cause serious injury and fall. Yes, it may also lead to the death of people. In addition, the steel belt seems to be some very small things. If there is a problem, it is indeed a bit serious.

In fact, for fiber laser cutting machines, the straightness of the track and the verticality of the entire machine are basically checked every six months. If these angles are found to be abnormal, they must be debugged in time. If this is not done, It is possible that the cutting effect is not very good, so this will increase the cutting error to some extent, and the drunk will also affect the cutting quality, which must be done.

In addition, each guide rail of the optical fiber cutting machine should be cleaned frequently to remove dust and other sundries, so as to ensure that the entire equipment is often wiped according to the normal rack. Any debris, the guide rails should be cleaned frequently, and lubricating oil should be applied on them, and the entire motor should be cleaned frequently, and the machine should ensure a good position during the traveling process.

How to Prolong The Service Life of The Machine In Daily Management

As a kind of equipment that is frequently used in industry, laser cutting machine has excellent overall performance, and can play a certain role in cutting different materials, and has a wide range of applications. So during the daily management, what basic knowledge do you need to master in the management of this type of cutting machine equipment?

First of all, the storage environment and operating environment of the laser cutting machine equipment are particularly important. It is recommended that the user must choose a dry and ventilated location, and it should not be placed in a place exposed to direct sunlight or in a dark and humid environment.

Secondly, after the purchase, if the laser cutting machine equipment cannot be put into use immediately and needs to be stored for a period of time, it is recommended that users read the product manual more when they are free to master how to operate correctly.

Not only that, there should be no harmful gas or odor in the operating environment of the laser cutting machine equipment. The operation and storage of such cutting equipment should be kept away from heat sources and open flames.

The laser cutting machine equipment should be managed by a special person every day. After the operation is completed, the corresponding cleaning and maintenance work should be done. It is also necessary to insist on cleaning the storage and operating environment every day to ensure that no impurities, dust and dirt will affect the cutting equipment. The performance and quality of the cutting equipment can be guaranteed to keep the performance of the cutting equipment in a good state and its service life can be longer.

The performance of laser cutting machine equipment is very diversified, and its role in many fields is irreplaceable. If you want to better utilize the performance advantages of cutting machine equipment and run more stably in the later stage, relevant personnel must be in daily management. Pay attention to details.

How to Maintain The Main System of The Laser Cutting Machine

1. Maintenance of cooling system

The water inside the water cooler must be replaced regularly, and the general replacement frequency is one week. Make sure that the laser tube is filled with circulating water before the machine works. The quality and temperature of the circulating water directly affect the service life of the laser tube. It is recommended to use pure water or distilled water, and control the water temperature below 35°C. If the water is not changed for a long time, it is easy to form scale, which will block the waterway, so be sure to change the water regularly.

2. Maintenance of dust removal system

After the fan is used for a long time, a lot of dust will accumulate in it, which will affect the exhaust and deodorization effect, and will also generate noise. When it is found that the suction power of the fan is insufficient and the smoke exhaust is not smooth, the fan should be cleaned. First turn off the power, remove the air inlet duct and air outlet duct on the fan, remove the dust inside, then turn the fan upside down, turn the fan blades inside until it is clean, and then install the fan. Fan maintenance cycle: about a month.

3. Transmission system maintenance

During the long-term cutting process of the fiber laser cutting machine, smoke and dust will be generated, and the fine dust will enter the equipment through the dust cover, and thus adhere to the rail rack, and the long-term accumulation will increase the wear of the rail rack. Rack guides are relatively precise accessories, and a large amount of dust is deposited on the surfaces of the guides and linear shafts for a long time, which has a great impact on the machining accuracy of the equipment, and will form corrosion spots on the surfaces of the linear shafts of the guides, shortening the service life of the equipment. Therefore, in order to make the equipment work normally and stably and ensure the processing quality of the products, it is necessary to do a good job in the daily maintenance of the guide rails and linear axes, and do regular dust removal and cleaning. After cleaning the dust, grease the rack and lubricate the rail with lubricating oil. Each bearing should also be filled with oil regularly, so as to maintain flexible driving, accurate processing and prolong the service life of the machine tool.

BuyCNC reminds you that during the working process of the machine, the operator must observe the working condition of the equipment at any time, if there is an abnormal situation, immediately cut off all power, remove the fault in time or report to the supervisor, and actively take corresponding measures. Regularly count the use of the machine, and keep a record of each part of the laser cutting machine. If the effect is not good, replace it in time to prevent problems before they occur.