The Infos About CNC router Controller

CNC Controller owned by BuyCNC

There are many CNC controller systems on the market now. Will you be confused when you choose CNC Controller?

At present, the embedded control system of engraving machine is divided into two categories: panel system with buttons and display system with mouse and keyboard. Our industry refers to them as integrated machine and split machine system.

Generally speaking, the control system of cnc engraving machine is controlled by computer or directly by the handle board. So what is the difference between choosing different control methods?

1. Using computer control: the computer completes all the calculation work. The computer is in working state when the engraving machine is working, and other typesetting work cannot be performed. The computer is in an exclusive state. This is the basic work pattern. The advantage is that you can use various programs on the computer to directly modify the patterns, so that your processed patterns can be sent to the engraving machine more quickly. The downside is that you need to use a computer. The principle is: use a board to connect to the computer, and then connect the line to the engraving machine control system.

2. Controlled by the handle board: the controller performs layout and direct operation while the engraving machine is working. The advantage is that it can be operated directly, which is convenient for some customers who do not use computers for the time being. The downside is that the buttons of the handle controller will easily break, and the design pattern needs to be designed in other places and sent to the controller.

BuyCNC provides a variety of controllers for you to choose from, including Mach 3, NC-studio, DSP controller, Syntec controller and so on. And we will help you choose the most suitable Controller system. Next, I will introduce you to these control systems.

The CNC router Controller Introduction

1.DSP control system:

This system is a handheld controller, which can control CNC machine without connecting to a computer. And through this system, you can put the created file in the USB flash drive, and then you can transfer the file to the DSP Controller system through the USB interface. However, it should be noted that the DSP control system has a storage space of 512M, and cannot place overly complex G codes. As the smallest controller, it is the most common choice for CNC router machines such as three-axis woodworking machines .

2.NC-Studio control system:

This controller is a system based on MS Windows 98 or MS Windows NT (2000 / XP). Using this control system, you can control the CNC router machine through the computer. Its advantage lies in 32-bit counting and multitasking cooperation. Compared with other systems, it has outstanding performance in high-speed precision, multi-task collaboration and network interconnection. It is usually used for high-performance CNC router machines.

3. Syntec control system:

The syntec control system is a completely independent control system, you can copy the created files to the CF card, and then connect the CF card to the Syntec system through the interface, and you can also load the design from the computer through the network cable program. The Syntec control system can control complex processing paths, and as a closed-loop control system, it is suitable for servo systems. Generally, it is suitable for large machines with servo motors, such as large mold manufacturing and automatic tool change CNC milling machines.

4.Mach3 control system:

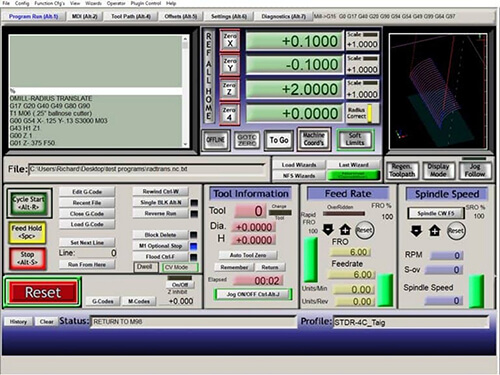

The Mach3 control system is the most common CNC control system. Its operation and maintenance are very convenient, and it supports a variety of file formats, including DXF, BMP, JPG and HPGL file formats. It also supports G codes created by G code design software such as Type3, Artcam, castmate, ProE, UG, etc. Now, this Controller system is widely used in various CNC router machines.

Features of Each CNC Router Controller

DSP controller:

The DSP remote control system is completely independent of the PC platform (the DSP does not need a PC when working), and can read files directly from the U disk, and easily process G code or PLT files of any size. It supports high and micro steps, which can be processed accurately and quickly. Support processing some files. Reliable data protection and recovery functions.

Syntec controller system:

Syntec is designed to use automatic tool change, multiple spindle heads and complex G codes that require advanced control of the machine.

Mach3 and NCstudio controller:

Both Mach3 and Nc sudio controllers require a PC to control the CNC machine. Mach3 controllers are very popular in the United States, Canada, Europe and Australia.NCstudio controller is a CNC controller in China, popular in China, South Asia and India.

If you want to know more about BuyCNC or want professional help in selecting machines and control systems, you can contact us through the dialog software in the lower left corner.