handheld fiber laser welder Video

Introduction of Handheld Laser Welding Machine

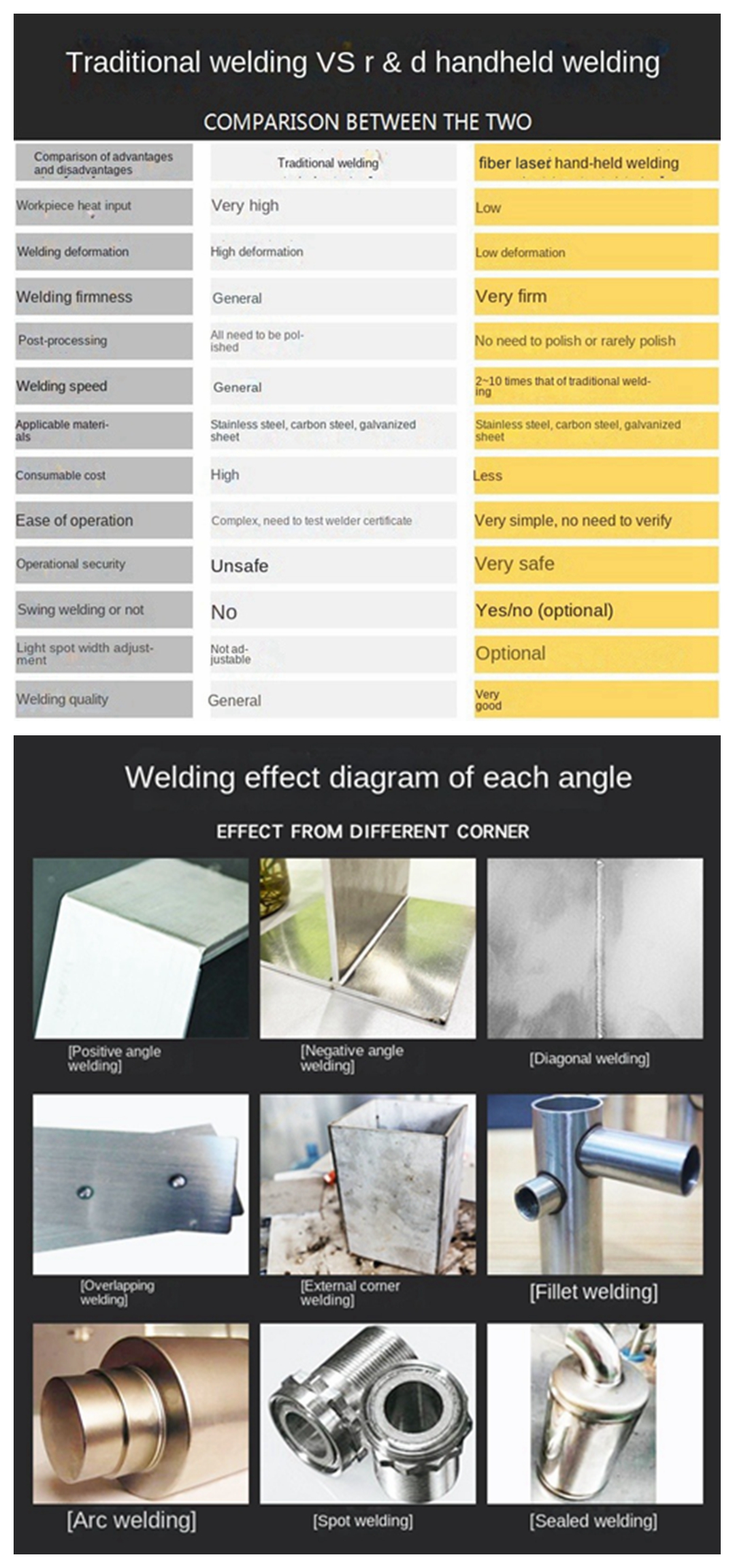

Handheld laser welding machine is a portable operation equipment, it can improve the welding defects such as undercut, incomplete penetration, dense pores and cracks in the traditional welding process. It is also a precision welding equipment, but it can respond freely. Flexible for applications in various environments.

For some production supplementary operations and packaging management, it can be easily applied in various types of environments, and has the characteristics of higher professional standards and reliability. The professional production goal of handheld fiber laser welder has the industry advantages of high standard and specialization. At the same time, in the process of guaranteeing the goal of accurate welding, it also realizes functional, practical and humanized design.

Advantages of aluminum laser welding machine:

1. The welding gun of the Handheld laser welding machine replaces the traditional fixed optical path, which is more flexible and convenient, realizes long-distance laser welding, and overcomes the limitation of the travel space of the worktable;

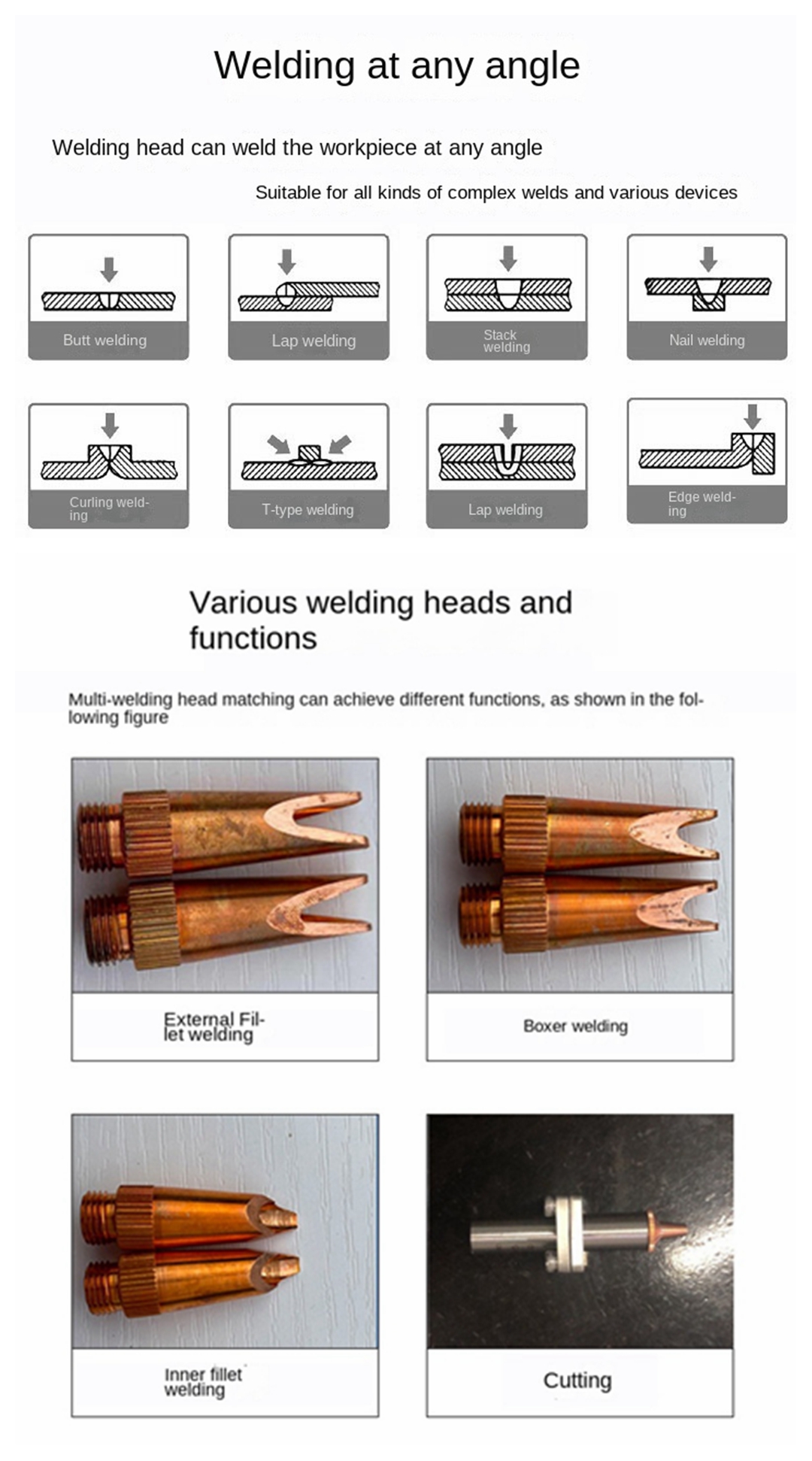

2. The handheld fiber laser welder’s hand-held welding head is light and flexible, easy to operate, and can meet welding of various angles and positions; it can weld any part of the workpiece at any point of view, is flexible and convenient, and can complete outdoor welding. All kinds of messy welds, spot welding of various equipment.

3. The hand-held welding head is equipped with 5 meters of imported optical fiber, which is flexible and convenient to realize outdoor welding. It can realize welding at any angle to the workpiece, intelligent switching of dual optical paths, and uniform distribution of time-sharing light energy.

4. The handheld fiber laser welding machine adopts infrared positioning, which is used for welding head position calibration and welding position verification. The welding position is more accurate and the welding seam is more beautiful.

5. Low maintenance cost: hand-held laser welding, no fine welding table, low material, low energy consumption, low equipment deployment and maintenance cost. In the same work environment, we need to spend a lot of time maintaining the welding station, and the manual laser setup equipment deployment can work as long as it is equipped with hand-held laser welding. As for replacement, the cost of accessories is low.

Applications of aluminum laser welder:

1. Kitchen and bathroom cabinets

At present, people often need to use a variety of kitchen cabinets, including some stainless steel kitchen utensils. Stainless steel kitchen utensils are usually made by splicing various plates in the production process, and the plates naturally need to be cut in the production process, and most of the cutting is done with a handheld laser welding machine.

2. Stairs and elevators

In the process of making elevators and stairs, especially some edges and corners need to be welded with an easy-to-operate handheld fiber laser welder to ensure that every edge and corner can be welded in place and ensure the aesthetics of the stairs and elevators, so the evaluation is high. The application of hand-held laser welding machines in stair elevators is also relatively common.

3. Door and window guardrails

More and more stainless steel materials are used in the process of modern home improvement, including some stainless steel doors and windows and guardrails, and stainless steel doors and windows and guardrails also need to be welded with welding equipment during the construction process. The well-received handheld laser welding machine plays such a role in ensuring that the display effect of doors, windows and guardrails will not be affected after welding.

Want to Get the Handheld Laser Welder Machine Price?Get Free Consultation Now!!!

Reviews

There are no reviews yet.