With the continuous development of the wood processing industry, CNC engraving machines, as representatives of modern woodworking machinery, have an increasingly wide range of applications. However, the prices of CNC wood router machines on the market vary greatly, which confuses many buyers. So, what factors are related to the price of wood CNC engraving machines? This article will provide you with a detailed analysis.

1. Brand factors

Brand is one of the important factors affecting the price of wood CNC engraving machines. Famous brands usually have higher brand value and market recognition, and their products are often more guaranteed in terms of quality, performance, and after-sales service. Therefore, the prices of well-known CNC wood router machines are relatively high. Some small or new brands may sell their products at lower prices in order to open up the market. However, it should be noted that a low price does not necessarily mean a high cost-effectiveness. When choosing, buyers also need to consider factors such as product quality and after-sales service comprehensively.

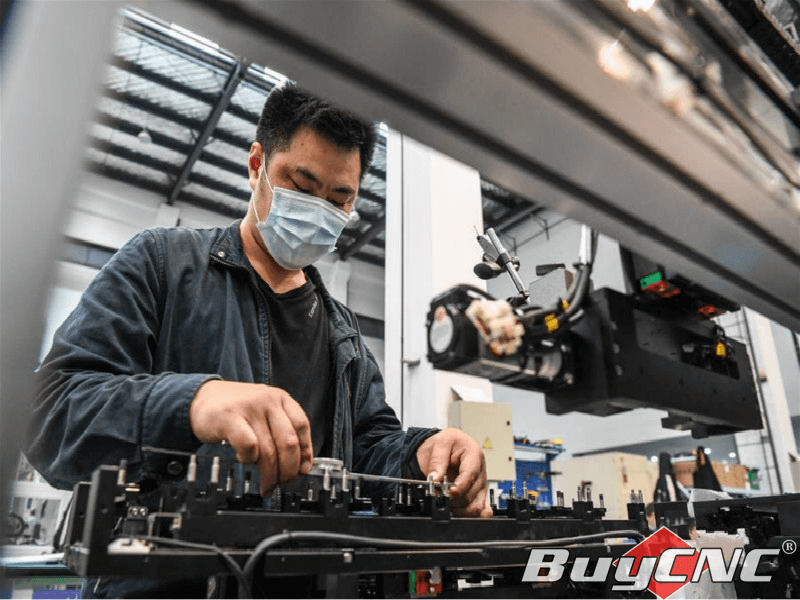

BuyCNC Co., Ltd. founded in 2000, is a leading CNC machine supplier in China, specializing in CNC machinery with rich experience! We are committed to providing the world’s customers with the best quality machines and perfect aftersales service and the most attractive price.

2. Configuration factors

3.Material cost

The material cost accounts for a considerable proportion of the production cost of wood CNC engraving machines. High quality raw materials and accessories can ensure the stability and durability of engraving machines, but they can also increase production costs, leading to an increase in product prices. For example, carving machines with cast iron bed frames are more stable than those with channel steel or square tube bed frames, but they are also more expensive.

4.R&D and technology investment

CNC engraving machines belong to high-tech CNC equipment, and their research and development and technological investment are also important factors affecting prices. Famous brands usually have stronger research and development capabilities and technological accumulation, and can continuously launch products with superior performance and richer functions. The R&D and technological investment in these products will also translate into higher product prices.

5.After sales service

Comprehensive after-sales service is an important guarantee for ensuring the normal operation and extending the service life of engraving machines. Famous brands usually have a more comprehensive after-sales service system, which can provide timely technical support and maintenance services. These services will also increase the added value of the product, leading to price increases.