Table of Contents

With the rapid development of CNC router machines, more and more people have begun to buy CNC machines. According to statistics, more and more buyers have chosen to buy CNC engraving machines with vacuum adsorption function. The price of this machine is a bit more expensive than the ordinary CNC router machine. So first of all, let me introduce to you what is CNC Machine with vacuum suction function and ordinary CNC Machine.

The Different Of Two Types of CNC Machine

Numerical control engraving machines are mainly divided into aluminum profile table engraving machines and vacuum adsorption table engraving machines according to their table tops. The former is to use aluminum profile as the countertop, and the engraved workpiece needs to be fixed manually with rivets or fixed with T-slot on the aluminum countertop. This fixing method is slower and needs to be re-fixed every time the material is changed. However, this aluminum type The table engraving machine is relatively cheap to process; while the vacuum adsorption table uses a vacuum pump to fix the material, place the material on the vacuum table and turn on the vacuum pump switch to automatically fix the material. This method can greatly increase the working speed and reduce manpower. labor. So now this kind of vacuum CNC router is becoming more and more popular. So do you know what this type of CNC router vacuum machine is made of? Next, I will introduce you to it.

What is the Vacuum System Of CNC Machine

Do you know why the Vacuum CNC router has a vacuum suction function, because it has a vacuum system for CNC router. This system makes it possible to fix the material by vacuum adsorption. This system is a combination of CNC router vacuum attachment. The three vacuum attachments are Vacuum work table, Vacuum zone control switch, and Rotary Vane Vacuum Pump. They make ordinary engraving machines have the function of vacuum adsorption.

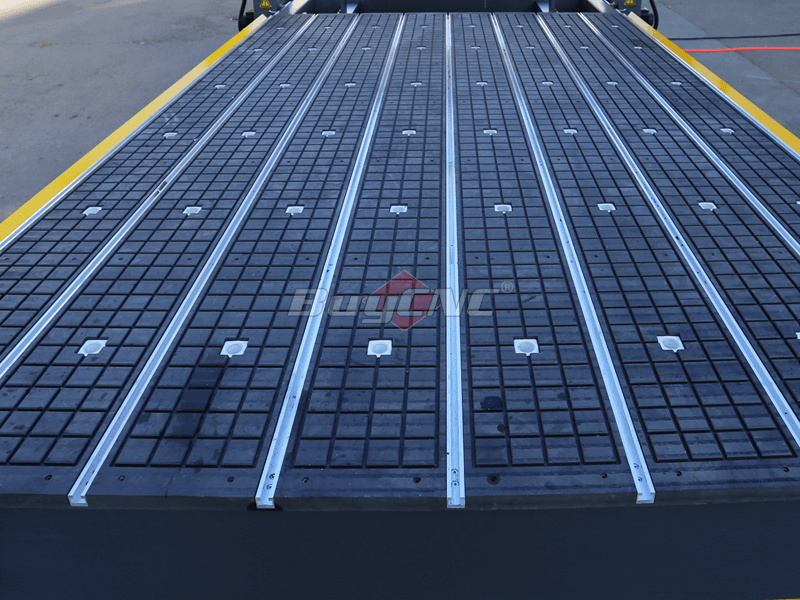

Vacuum Work Table

The material of the vacuum suction table is generally hard PVC or Bakelite, because this material is relatively strong.The vacuum CNC engraving machine uses a vacuum pump to connect to the bottom of the CNC Router table. There are multiple vacuum suction holes on the vacuum work table. Therefore, when the worker puts the material on the vacuum worktable of the engraving machine, the processed material is firmly adsorbed on the worktable by the negative pressure generated by the vacuum pump. The entire process of fixing the material is less than 10 seconds, which can greatly improve the processing efficiency and processing speed. Vacuum suction table cutting requires no air leakage, so it is not suitable for processing hollow boards and heterogeneous boards. It is suitable for processing materials: ordinary density boards of about 2 cm are very suitable. It’s too thin and inappropriate, and it will sink when you suck it. If it is too thick, the vacuum suction function may not work.

Vacuum Zone Control Switch

The surface of the vacuum table is multi-zoned, generally divided into four, six or eight small areas. This allows the operator to easily switch from overall machining to smaller part machining (requiring smaller segmented areas). The Vacuum zone Controller on the fuselage is to control the adsorption function of the zones. Each zone has its corresponding switch. We can easily open and close the vacuum zone through the controller.

Rotary Vane Vacuum Pump

The rotary vane vacuum pump is one of the main pump types for obtaining low and medium vacuum pumps. It can be divided into oil-sealed pumps and dry pumps. According to the required vacuum degree, single-stage pumps and two-stage pumps can be used, among which two-stage pumps are more common.

The rotary vane vacuum pump is mainly composed of a pump body (stator) and a rotor. More than two rotary vanes are installed in the rotor slot, and some pumps are also equipped with springs between the rotary vanes. The rotor is eccentrically installed in the pump cavity, and the gap between its outer edge and the top surface of the pump cavity is 2 to 3 microns. When the rotor rotates, under the action of centrifugal force, the rotary vane slides back and forth along the groove and always keeps contact with the inner wall of the pump cavity, dividing the pump cavity into two or several variable-volume working rooms.

When the rotor rotates clockwise, the volume of the suction chamber communicating with the suction port gradually increases from zero, the gas pressure in the cavity decreases, and the pumped gas is continuously sucked in from the suction port. At the same time, the volume of the exhaust chamber communicating with the exhaust port is reduced from large to small, and the gas in the suction chamber is compressed. When the gas pressure is higher than the atmospheric pressure, the exhaust valve is opened to discharge the atmosphere. The rotor continuously rotates and the pump continuously pumps air.

The Actual Effect of Vacuum Adsorption Table

In order to understand the vacuum bed for CNC router, we specially found a CNC engraving machine with vacuum adsorption function. Let’s take a look at the actual effect of the vacuum adsorption table.

1. Open the vacuum valve and do the next test. You will find that the absorption of flat wood boards is better. However, the adsorption effect of curved and uneven plates is not good.

2. Carved wooden door products, embossed products and other non-carved products have a good adsorption effect. However, the absorption effect of hollow carving products that are cut through and cut through is not good.

3. In terms of time, manual fixation takes 2-4 minutes. The vacuum adsorption takes only 1-2 minutes. Time is better than manual fixation.

The vacuum suction woodworking engraving machine has good practical performance. Woodworking engraving machine users can choose the most suitable model according to the products they engrave.

There are many kinds of woodworking engraving machines on the market, there are plywood fixed table woodworking engraving machines and vacuum adsorption fixed woodworking engraving machines.

The price of vacuum adsorption woodworking engraving machine is relatively expensive. The structure of the vacuum adsorption woodworking engraving machine is composed of a vacuum adsorption table and a vacuum pump. In the market, there are generally six partitions for vacuum adsorption and eight partitions for vacuum adsorption. The vacuum suction table is composed of a point wood board with a thickness of about 5 cm, and the material is very hard. Punch six or eight holes on the top to achieve the function of strong suction.

Precautions for Operating the Vacuum Pump

1. Before using the rotary vane vacuum pump, first ensure that the pump is clean to prevent debris from entering the pump. Check the oil level, it is advisable to fill the oil to the center of the oil mark when the pump is stopped. If it is too low, the exhaust valve cannot seal the oil and affect the vacuum degree. Too high will cause fuel injection when starting to open to the atmosphere. During operation, the oil level has increased, which is a normal phenomenon.

The oil adopts the clean vacuum pump oil of the specified brand and is added from the oil injection hole. After refueling, screw plugs on. The oil should be filtered to prevent debris from entering and clogging the oil hole. Add the oil to the vacuum pump according to the indication scale of the oil standard. Rotate the three-way valve to make the suction pipe of the pump communicate with the atmosphere and isolate it from the evacuated container, and open the exhaust port.

2. When the ambient temperature is too high, the temperature of the oil increases, the viscosity decreases, and the saturated vapor pressure will increase, which will cause the ultimate vacuum to drop, especially the total pressure measured with a thermocouple. BuyCNC believes that the ultimate vacuum can be improved if ventilation and heat dissipation are enhanced, or the pump oil performance is improved.

3. Vacuum pumps should not be used to pump out gases that have high oxygen content, are explosive, and are corrosive to metals. In addition, it is not advisable to inhale gas that can react with pump oil and gas containing a large amount of water vapor, etc.

4. The pump can be started at one time under the atmosphere or any vacuum degree. If the pump port is connected with a solenoid valve, it should be operated at the same time as the pump.

5. After the pump is running normally, slowly rotate the three-way valve to make the suction pipe of the pump communicate with the evacuated container and isolate it from the atmosphere.

6. Rotate the pulley by hand to check the operation. After there is no abnormality, turn on the power again and pay attention to the direction of rotation.

7. After using for a period of time, the belt becomes slack, and the position of the motor needs to be adjusted. Pay attention to replenishing the pump oil. If there is debris or water in the pump oil, replace the oil and clean the pump body. It is not allowed to clean the pump body with volatile liquids such as ethyl acetate and acetone.

8. Check the ultimate vacuum of the vacuum pump with a compressed mercury vacuum gauge. If the gauge is fully pre-pumped, the pump temperature is stable, and the pump port is directly connected to the gauge. The ultimate vacuum will be reached within 30 minutes of operation. The value measured by the total pressure gauge is related to the error of the pump oil, the vacuum gauge, and the regulation. Sometimes the error may even be large. BuyCNC thinks it can only be used as a reference.

9. If the relative humidity is high, or the pumped gas contains more condensable steam, the gas ballast valve should be opened after the pumped container is connected, and the gas ballast valve should be closed after 20-40 minutes of exercise. Before stopping the pump, the gas ballast valve can be opened for 30-minute no-load movement to extend the life of the pump oil.

10. When you stop using the pump, if you want to maintain a certain degree of vacuum in the vacuum system, you should rotate the three-way valve to close the vacuum system and the suction pipe of the pump communicates with the atmosphere. Cut off the power and stop the operation. Close the exhaust port and close the pump cover tightly.