Table of Contents

With the rapid development of science and technology, the stone cnc machine industry has also ushered in unprecedented changes. The application of automation and intelligent technology not only improves the processing efficiency of stone cnc machines, but also greatly simplifies the operating process, bringing new development opportunities to the stone processing industry.

Automatic operation of stone cnc machines

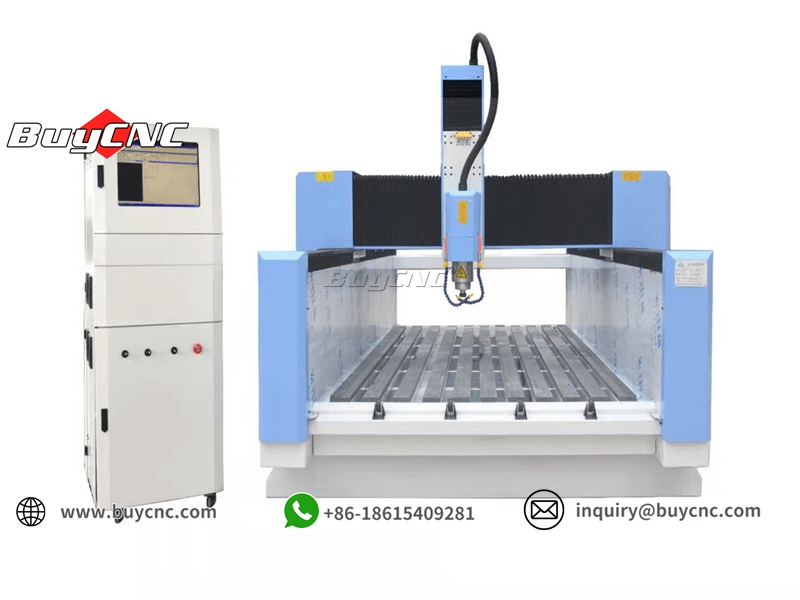

First of all, the automated operation of stone cnc machines has been widely used. Traditional stone processing often relies on manual operations, which is not only inefficient but also susceptible to interference from human factors. However, with the introduction of automation technology, stone cnc machines have been able to automate a series of processes from stone transportation, cutting, polishing to engraving. These automated stone cnc machines are usually equipped with high-precision sensors, intelligent control systems and advanced robotic arms, which can accurately complete various complex processing tasks.

Automated operations not only improve the efficiency of stone processing, but also reduce labor costs. In the stone processing process, many processes need to be repeated. If you rely on manual operations, it will not only be labor-intensive, but also error-prone. The automated stone cnc machine can work 24 hours a day, which not only reduces manual participation, but also greatly improves the accuracy and stability of processing.

The intelligence of stone cnc machines

Of course, just realizing automated operations is not enough to meet the needs of modern stone processing. With the continuous development of artificial intelligence technology, intelligent control systems have also been widely used in stone cnc machines. The intelligent control system can automatically adjust the processing parameters of the stone cnc machine through real-time analysis of processing data to achieve optimal processing results. In addition, the intelligent control system can also realize fault warning and remote maintenance, improving the reliability and service life of the equipment.

The application of intelligent control systems further simplifies the operation process of stone cnc machines. Traditional stone processing requires operators to have rich experience and skills, while intelligent control systems can transform these complex operating processes into simple instructions or parameter settings. Operators only need to perform simple operations through the touch screen or computer interface to complete complex processing tasks. This simplified operation process not only reduces the difficulty of operation, but also improves work efficiency.

Explore new technologies in stone cnc machines

In addition to the application of automation and intelligent technology, the stone cnc machine industry is also constantly exploring new technical routes and solutions. For example, by introducing machine vision technology, the stone cnc machine can automatically identify and locate the stone surface, thereby improving the accuracy and efficiency of processing; by introducing the Internet of Things technology, the stone cnc machine can achieve interconnection with other equipment and realize the production process. Intelligent management and optimization.

To sum up, the automation and intelligence of stone cnc machines have reached a new height. The application of automated operations has greatly improved the efficiency and quality of stone processing, while the introduction of intelligent control systems has further simplified the operating process and reduced the difficulty of operation. In the future, with the continuous advancement and application of science and technology, the stone cnc machine industry will usher in broader development prospects. We look forward to seeing the application of more innovative technologies and bringing more surprises and breakthroughs to the stone processing industry.