Table of Contents

Application areas of laser cleaning

With the development of laser cleaning technology, laser cleaning technology has been popularized in many industries in industrial applications, as follows:

Microelectronics field: semiconductor components, microelectronic devices, memory templates, etc.;

Cultural relics protection: stone carvings, bronzes, glass, oil paintings and murals, etc.;

Abrasive cleaning: rubber molds, composite molds, metal molds, etc.;

Surface treatment: hydrophilic treatment, surface roughening, treatment of welds before and after welding, etc.;

Paint and rust removal: aircraft, ships, weapons and equipment, bridges, metal pressure vessels, metal pipes, etc.; aircraft parts, electrical product parts, etc.;

Others: urban graffiti, printing cylinders, building exterior walls, nuclear industry, etc.

Application Research of Metal Surface Laser Cleaning Technology

1. Laser cleaning not only removes dirt but also improves corrosion resistance

Laser cleaning technology can overcome the shortcomings of traditional cleaning technology, such as time-consuming and laborious, environmental pollution and so on. It plays an important role in removing dirt on the metal surface.

In addition, the laser cleaning parameters can be further controlled to make the cleaned metal surface react chemically and form a protective layer several microns thick, which can prevent the metal from further rusting. Using laser cleaning technology to decontaminate can improve the corrosion resistance of metal devices by 3-4 times.

2. Choosing the right laser type and wavelength has an important impact on the cleaning effect

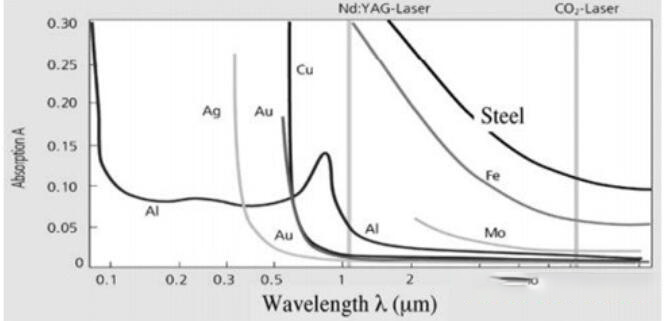

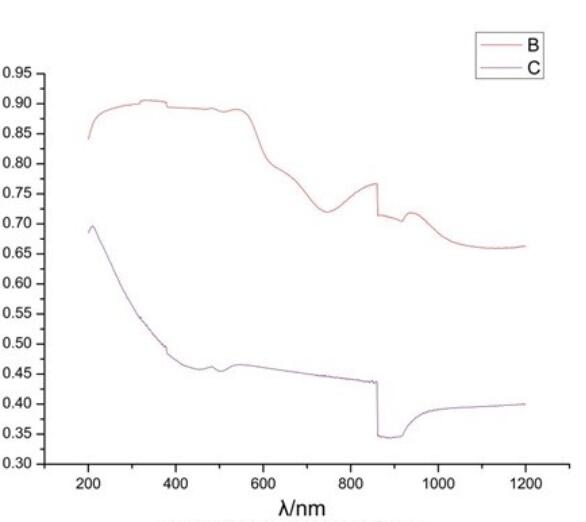

The first picture shows the trend of absorption coefficients of various metals with wavelength, which is shown in λ= At 916nm~1200 nm, most metals have high absorption coefficients in this band, and organics have relatively strong laser absorption in this band.

For this reason, fiber lasers have unique advantages in all aspects in terms of absorptivity. The organic pollution layer absorbs laser strongly, and the temperature of the organic pollution layer rises rapidly to the evaporation point for gasification, so as to achieve the purpose of removing the pollution layer without damaging the substrate.

Then determine the energy threshold of laser cleaning, which will determine the effect of laser cleaning. Choosing the appropriate laser cleaning energy threshold requires us to comprehensively consider the effects of material properties, microstructure, morphological defects, laser wavelength and pulse width.

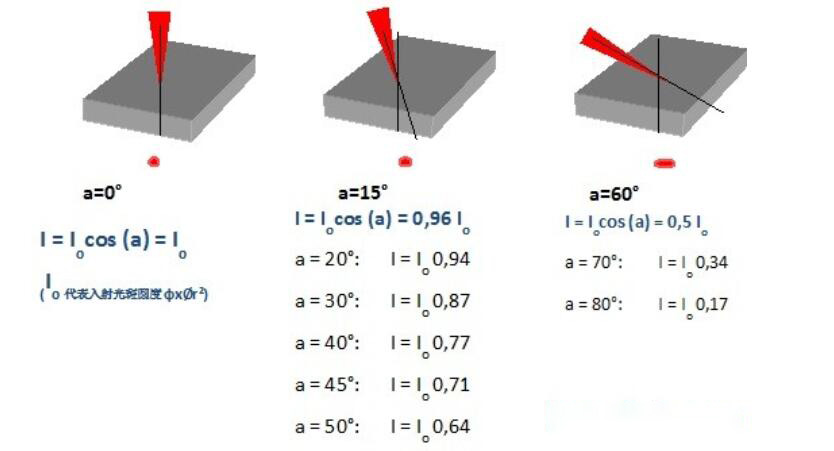

3. The appropriate laser incidence angle makes the cleaning effect twice the result with half the effort

When the laser is incident at a certain inclined angle, the laser directly radiates below the adhesive particles, resulting in higher thermoelastic stress. Compared with the vertical incidence, the pollutants are easier to be removed. In addition, the study found that with the increase of the tilt angle, the laser radiation area is wider (see Figure 4). When the tilt angle is 20 degrees, the area of the cleaned area is about 10 times that of the vertical incidence, which effectively improves the efficiency of laser cleaning.

4. The correct defocus amount improves the laser cleaning effect

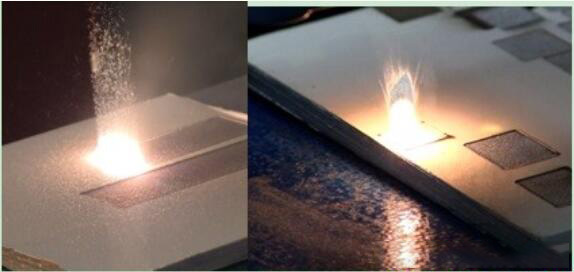

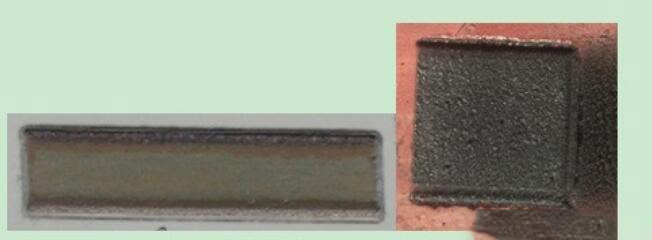

The cleaning mechanism will be different with different defocusing amount. Cleaning is the mechanism of explosive fragmentation of surface materials when defocusing, and when defocusing becomes larger, the removal of paint layer changes from fragmentation to vaporization. The red frame in the first picture above, in the defocus test, there will be dust around the cleaning place, which is obviously the remaining ashes of the paint burning. In the second picture, the principle of fragmentation is used, and there is no ash.

In order to optimize the effect of laser cleaning of metal surface, it is necessary to comprehensively consider the laser cleaning method, cleaning model, laser type, laser wavelength, energy density, power, pulse frequency, pulse time, laser incidence angle and other process parameters.

Pulse laser can effectively clean the corrosion on the surface of carbon steel. When the wavelength is 1064nm, the laser power is 500W, the pulse frequency is 10kHz, the pulse width is 120ns, the cleaning speed is 60mm/s, and the lap rate is 5%, the laser cleaning corrosion effect is the best. No oxygen element is found on the surface, micro areas, lines and points of corrosion by laser cleaning. Only by systematically studying the process parameters can an efficient laser cleaning system be formed.

Laser cleaning will become the general trend of cleaning market development

Although laser cleaning cannot completely replace the traditional cleaning technology at present, with the progress of science and technology and the improvement of environmental protection requirements, laser cleaning will become the general trend of the development of the global cleaning market.

By developing new laser cleaning systems and equipment and optimizing the cleaning process, improving the cleaning efficiency, reducing the cleaning cost, reducing the damage of the surface to be cleaned, and realizing the green, efficient and automatic cleaning process of metal surface is bound to be the demand of the future market.

Buycnc as a national key high-tech enterprise specializing in the R & D, production and sales of fiber lasers and their key devices and materials, has the ability to vertically integrate the industrial chain from materials, core devices to complete machines.

At present, the 100W-2000W pulse special cleaning laser launched by buycnc laser for the laser cleaning field has been widely used in surface treatment, mold cleaning, paint and rust removal and other hardware manufacturing, automobile and rail transit fields. Buycnc can also provide customized cleaning solutions for different application needs. Later, I will continue to share with you the application cases of laser cleaning.

Laser Cleaning Machine For Sale