Table of Contents

The efficient and precise rust removal capabilities of hand held laser rust removers have been widely recognized. In order to ensure the long-term stable operation of the machine and extend its service life, regular maintenance work is crucial. This article will provide a detailed analysis of the maintenance cycle and cost of handheld laser rust removal machines to help users better understand and manage the equipment.

Maintenance cycle of hand held laser rust remover

The maintenance cycle of a hand held laser rust remover usually depends on multiple factors, such as frequency of equipment use, working environment, work intensity, etc. Generally speaking, it is recommended that users develop maintenance plans based on the following principles:

1.Daily maintenance: After each use of the equipment, the machine should be cleaned, including removing dust, oil and other debris on the surface of the machine to ensure that the vents are not blocked. At the same time, check whether the power cord, plug and other parts of the equipment are intact to avoid safety hazards.

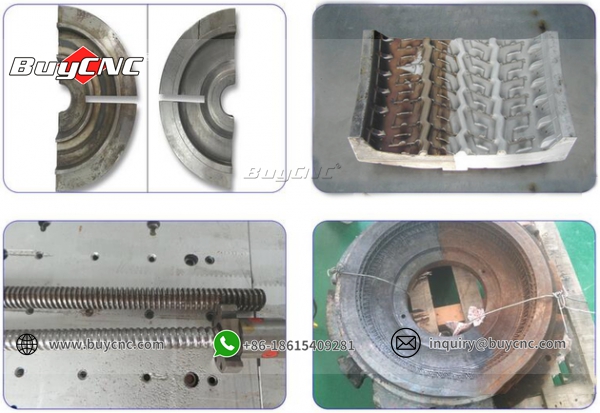

2.Periodic maintenance: Depending on the usage of the equipment, it is recommended to conduct a comprehensive inspection of the machine every once in a while (such as a month or a quarter). This includes checking whether the laser’s power, optical system, cooling system, transmission components, etc. are working properly, as well as checking whether the fasteners inside the machine are loose.

3.Annual maintenance: Perform in-depth maintenance at least once a year, including comprehensive disassembly, cleaning, lubrication, and replacement of wearing parts. This helps ensure the equipment remains in top condition for another year of use.

Maintenance cost analysis of hand held laser rust remover

The maintenance cost of hand held laser rust remover mainly includes the following aspects:

1.Labor cost: Depending on the maintenance cycle and the complexity of the maintenance content, corresponding labor costs need to be invested. This includes cleaning work for daily maintenance, inspection and adjustment work for periodic maintenance, and in-depth maintenance work for annual maintenance. Users can choose appropriate maintenance personnel or entrust a professional maintenance team to perform maintenance according to the actual situation.

2.Parts cost: During the maintenance process, some wearing parts or consumables may need to be replaced, such as filters, lenses, seals, etc. The cost of these parts varies depending on the make, model and quality. Users can choose suitable parts for replacement according to the equipment manual or the recommendations of the maintenance team.

3.Repair costs: If equipment malfunctions or is damaged, repairs may be required. The cost of repair depends on the nature and severity of the fault. For general faults, users can repair them themselves by consulting the equipment manual or consulting the maintenance team; for complex faults, it may be necessary to entrust a professional maintenance team to perform repairs.

Maintenance measures for hand held laser rust remover

In order to reduce maintenance costs, users can take the following measures:

1.Strictly follow the equipment instructions for operation and maintenance to avoid equipment damage caused by improper use.

2.Perform regular maintenance on equipment to discover and solve potential problems in a timely manner to avoid expansion of faults.

3.Choose parts and consumables with reliable quality and high cost performance to ensure the normal operation of the equipment.

4.Establish equipment files to record equipment maintenance and repair status to provide reference for subsequent maintenance.

To sum up, the maintenance cycle and cost of hand held laser rust remover vary depending on the equipment usage and maintenance requirements. Users should formulate a reasonable maintenance plan based on the actual situation, and take corresponding measures to reduce maintenance costs to ensure long-term stable operation of the equipment and extend its service life.