How does a laser cutter work?

In recent years, the application range of laser cutting technology has become wider and wider, and it has developed rapidly. Compared with traditional oxyacetylene, plasma, and other cutting processes, laser cutting machines have the characteristics of high flexibility, fast cutting speed, wide cutting materials, and high cutting quality. Therefore, laser cutting machine is commonly used in industrial manufacturing applications and popular among schools, small businesses, and hobbyists. Before officially explaining the working principle of laser cutting machine, we must understand the development of this important technology of laser cutting.

The creation of Laser Cutting Technology.

The emergence of laser cutting technology is a more convenient and faster cutting method based on improving traditional cutting technology. For example, the traditional CNC shearing machine can only use for linear cutting, while the laser cutting machine has multi-function operations. In traditional flame-cutting, the thermal deformation is substantial when cutting thin plates, which affects the cutting quality and wastes materials.

However, this situation will not happen at all when using laser cutting machines. The laser cutting machine has gradually replaced the traditional cutting process. And the application range has become more and more extensive. The Western Electrical Engineering Research Center manufactured the world’s first laser cutting machine. This machine was used for drilling diamond abrasive tools in 1965. Behind this successful case is the theoretical basis of “laser can increase production speed” in the genius Albert Einstein’s “Quantum Theory of Radiation” in 1917. To this day, we are impressed by the birth of this great technology, which has solved traditional cutting technology problems.

There are two main types of laser machines, CO2 laser cutting machines, and fiber laser cutting machines. Although these two types of cutting belong to laser cutting, there are obvious differences between the two. These differences are reflected in the working principle, price, cutting speed, stability, and cutting quality. Below, I will introduce how the CO2 laser and the fiber laser work principle.

The working principle of CO2 laser cutting machine ?

The laser of the CO2 laser cutting machine is a molecular laser. The main gas working in the laser is carbon dioxide, and the auxiliary gas is nitrogen, xenon, and hydrogen. The ratio of the three gases and the total pressure can be changed within a certain range, usually CO2:N2:He=1:0.5:2.5. And the total pressure is 1066.58pa. The CO2 laser cutting machine’s core uses the transition between the vibration and rotation energy levels of CO2 molecules to generate laser light.

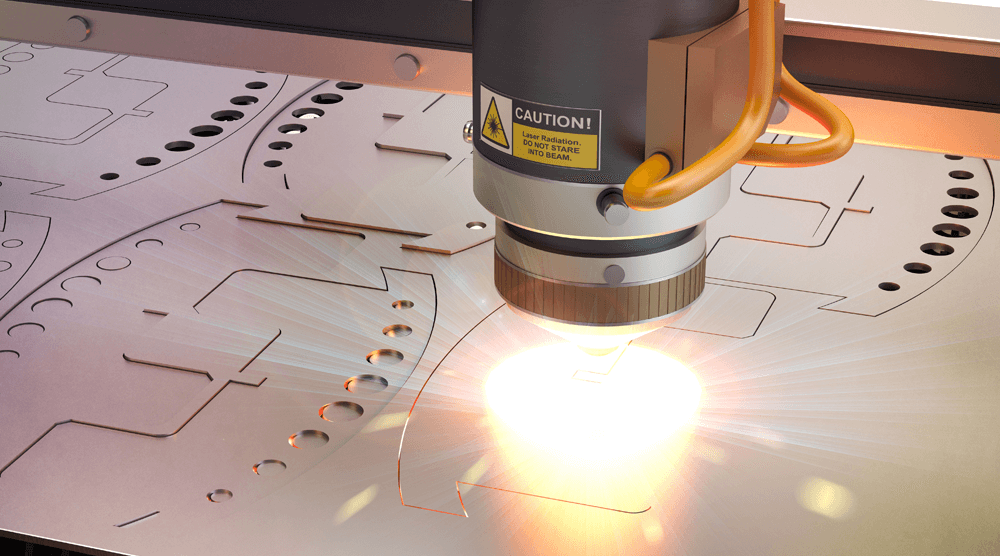

The laser beam’s wavelength in a carbon dioxide laser is in the infrared part of the spectrum, which is invisible to the human eye. The laser beam is emitted from the laser resonator’s beam channel that manufactures the beam and has a diameter of 3-4 inches. The reflector in the CO2 laser cutting machine can reflect the beam in different directions. The laser beam passes through the nozzle to focus together to form larger energy, which is enough to achieve cutting.

In the process of using CO2 laser cutting machine, pay attention to the following points. First of all, the laser beam of the carbon dioxide laser cutting machine should be accurately focused on the nozzle center. The energy density and focus form of this point should be completely consistent and circular. In this way, it can be ensured that the heat density is high enough when focusing on a single point of the material and cutting. Secondly, in the cutting process of non-metallic materials such as plastics. The CO2 laser cutting machine may produce toxic smoke when the materials are melted. Therefore, to ensure safety, the CO2 laser cutting machine must be placed in a ventilated outdoor environment.

Of course, thick metal materials such as copper and aluminum cannot be cut with a CO2 laser cutting machine. Because the copper and aluminum surfaces are smooth. A large amount of laser light will be reflected, reducing the cutting effect. Therefore, we recommend using a fiber laser cutting machine for metal materials such as copper and aluminum. The following will introduce in detail how the fiber laser cutting machine works.

The working principle of fiber laser cutting machines

Unlike CO2 laser cutting machine, the laser of fiber laser cutting machine is solid state. Fiber laser cutting technology uses solid gain media instead of carbon dioxide gas or liquid. This fiber laser cutting machine is very suitable for cutting reflective metal materials. Therefore, fiber laser cutting machines are developing rapidly in the metal cutting industry. In 2008, EuroBlech launched the first batch of fiber lasers, which are simpler and more durable. First, the laser light generated by the fiber laser cutting machine’s diode passes through an optical cable containing rare earth elements. The light is amplified at this time. Then, the fiber laser cutting machine’s lens focuses the light on forming an accurate cutting laser beam.

High energy conversion rate is one of the big advantages of fiber laser cutting machine. Authoritative data shows that about 75% of the received power is converted into a laser beam, which is an amazing number compared to the 20% conversion rate of a CO2 laser cutting machine. Besides, as mentioned earlier, fiber laser cutting machines use “seed lasers” to generate light beams amplified by diodes. In terms of intensity, a fiber laser beam is approximately 100 times that of a carbon dioxide laser. This also means that the fiber laser cutting machine can be applied to both metallic and non-metallic materials. A fiber laser cutting machine can do both plane cutting and bevel cutting. The fiber cutting machine equipped with a rotating shaft can also cut some metal pipes. Fiber laser cutting machine is energy-saving and environmentally friendly and is the most advanced laser cutting technology.

Most of the customers who have laser cutting needs will ask me how to choose between a fiber laser cutting machine and a CO2 laser cutting machine? What is the difference between these two machines? What are the advantages of the more expensive fiber laser cutting machine? Here is an answer to these questions.

Advantages of fiber laser cutting machine.

Co2 laser cutting machine is different from fiber laser cutting machine in many aspects, such as working principle of laser cutting machine, speed, maintenance, and other issues. The previous article describes the working principle of laser cutting machine and CO2 laser cutting machine and the difference of laser source to not repeat them here. The following will focus on the speed, cutting quality, and maintenance issues of both.

1. Fiber laser cutting machine has an extremely high cutting speed.

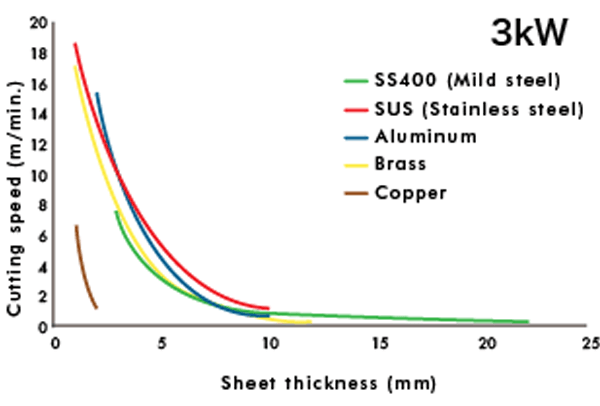

The fiber laser cutting machine’s cutting speed is twice that of the same power CO2 laser cutting machine and 4-5 times that of the YAG laser cutting machine. Therefore, the fiber laser cutting machine is very suitable for mass processing and production. The fiber laser cutting machine’s cutting speed is 10m/min.And the maximum positioning speed can reach 30m/min, which is far greater than the speed of wire cutting. Besides, the positioning accuracy of the fiber laser cutting machine is 0.05mm, and the repeat positioning accuracy is even as low as 0.02mm while meeting the needs of finishing. The following figure provides the cutting diagram of a 3000w fiber laser cutting machine for materials of different thicknesses for your reference.

2. Fiber laser cutting machine has excellent cutting quality.

The fiber laser cutting machine has a small focus spot and large energy, coupled with the imported fiber laser cutting machine’s stable performance, which ensures higher work efficiency and better cutting quality. And the fiber laser cutting machine has high photoelectric conversion efficiency, strong, flexible light guiding effect, small structure, and simple operation.

3. The fiber laser cutting machine does not require post-maintenance.

The use cost and maintenance cost of fiber laser cutting machines are meager. The fiber laser cutting machine’s power consumption is only 20-30% of a similar CO2 laser cutting machine. Because the fiber laser cutting machine transmits energy through the optical fiber laser, it does not need a working gas and reflective lens, which greatly reduces the cost. Besides, the fiber laser cutting machine has the advantages of adjustment-free, maintenance-free, and high stability, which reduces the cost of accessories and maintenance time.

4. Fiber laser cutting machine has widely use.

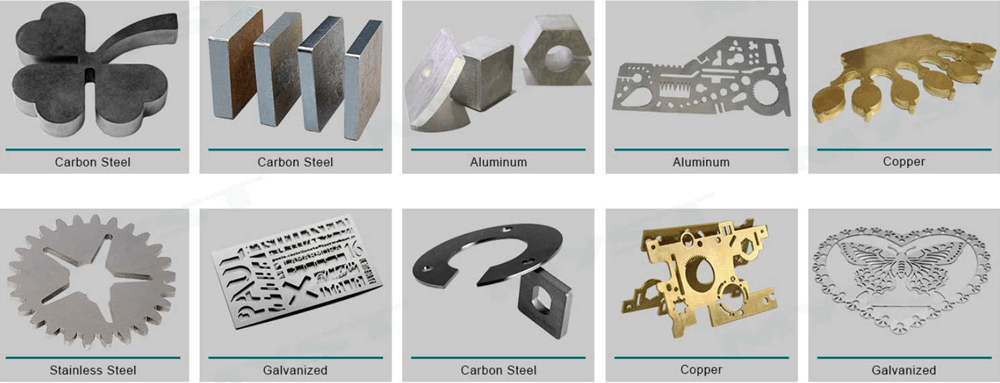

Fiber laser cutting machines can be used in sheet metal processing, auto parts, household appliances, craft gifts, advertising, and decoration industries. It is suitable for cutting metal materials in various manufacturing and processing industries. Stainless steel, carbon steel, copper, silver, gold, and other metal plates and tubes can cut with fiber laser cutting machines. If you can’t judge whether the cutting material can be cut with a fiber laser cutting machine, please contact us for free.

Fiber laser cutting machine has broad development prospects in the future.

Generally speaking, fiber laser cutting machine has vast development prospects. The appearance of fiber laser cutting machine is the advancement of human technology and our wisdom’s crystallization. The fiber laser cutting machine has had a significant impact on the manufacturing industry, and it has changed your production. If you have any questions, please contact us immediately, and we will provide you with the best solution.