Table of Contents

In the modern construction and decoration industries, stone is favored for its unique texture and durability. However, the original form of stone often cannot meet the needs of design and construction, which requires a series of processing, such as cutting, grinding, polishing, etc. At the same time, cleaning stone is also an important part of maintaining its beauty and extending its service life. As the key equipment for modern stone processing, the cnc machine for stone not only provides a series of services from rough processing to fine processing, but also adds stone cleaning services, providing more comprehensive support for the wide application of stone.

CNC machine for stone cutting, grinding and polishing services

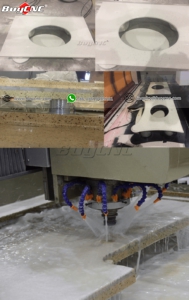

CNC machines for stone are widely and efficiently used in cutting, grinding, and polishing. Through high-precision cutting technology, the cnc machine for stone can cut stone into various shapes and sizes according to needs. Then, using professional grinding tools and techniques, the cnc machine for stone carefully polishes the surface of the stone to make it smooth and flat. Finally, the high-speed rotating polishing wheel and professional polishing agent deeply polish the stone surface, presenting a delicate, smooth and bright texture. These processing services not only enhance the beauty of the stone, but also enhance its durability and water resistance.

CNC machine for stone cleaning services

The cleaning service provided by the cnc machine for stone is an indispensable part of the stone processing process. During the long-term use of stone, dust, stains and other attachments are easy to accumulate on the surface. These pollutants not only affect the beauty of the stone, but may also cause damage to the stone. Therefore, it is important to clean the stone regularly.

cnc machine for stone cleaning services usually include the following steps: First, use a clean towel or a professional cleaning machine to remove dust, glue and other attachments on the stone surface. Then, select an appropriate cleaning agent based on the pollution status and source of the stone, and use a towel or brush to apply the cleaning agent to the contaminated area. The choice of cleaning agent is crucial, as inferior cleaning agents may cause more serious stone problems. Therefore, it is particularly important to choose high-quality products from reliable manufacturers. Next, use clean water to remove residual cleaning agent until the pH value reaches between 7-8. Finally, let the stone dry naturally to avoid contact with pollutants, rain, dust, etc.

During the cleaning process, the cnc machine for stone can perform customized operations according to different stone types and pollution levels to ensure the best cleaning effect. At the same time, cleaning services can also be combined with stone polishing to further enhance the gloss and beauty of the stone.

One-stop stone machining and cleaning services

The one-stop stone processing and cleaning service provided by the cnc machine for stone brings great convenience to customers. Customers only need to inform the cnc machine for stone manufacturer of their needs, and they can obtain a series of processing services from cutting, grinding, polishing to cleaning. This one-stop service not only simplifies the processing process, but also improves processing efficiency and quality, saving customers valuable time and energy.

In short, as a key equipment for modern stone processing and cleaning, the cnc machine for stone provides more comprehensive and efficient support for the wide application of stone. By providing a series of services from cutting, grinding, polishing to cleaning, cnc machines for stone meet customers’ diverse needs for stone quality and appearance, and promote the development and progress of the stone industry. With the continuous advancement of science and technology and the continuous improvement of technology, it is believed that cnc machines for stone will play a more important role in the field of stone processing and cleaning in the future.