Table of Contents

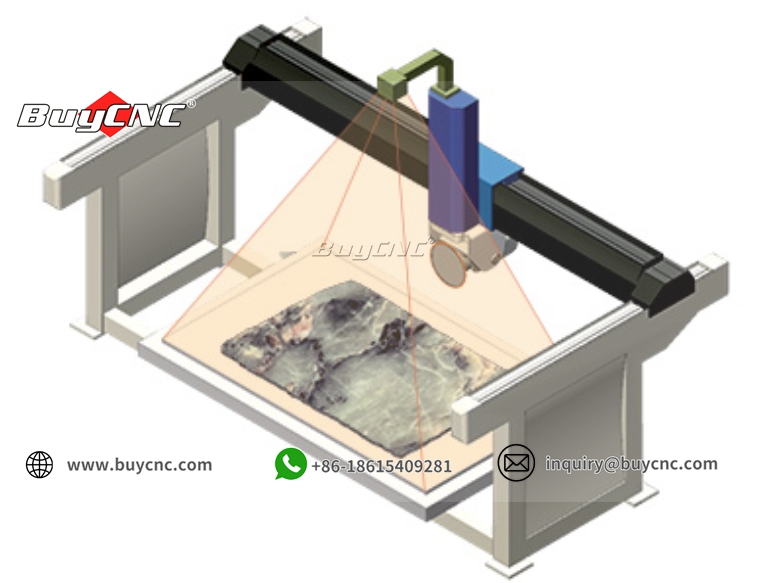

In the stone processing industry, cnc stone cutting machines are core equipment, and their operation safety is directly related to production efficiency and personnel safety. However, during stone processing, safety hazards such as stone fragmentation or falling off may occur from time to time due to factors such as material characteristics, equipment status, and improper operation. Therefore, it is crucial to develop and implement an effective set of coping strategies.

Understand the stone characteristics and risks of cnc stone cutting machines

First of all, you must have a full understanding of the stone being processed. Different stones have different hardness, toughness and brittleness. These factors determine the stability of the stone during processing. Therefore, before processing, the stone should be tested and analyzed in detail to understand its physical properties and processing difficulty in order to formulate a suitable processing plan.

Optimize cnc stone cutting machine configuration and maintenance

The configuration and maintenance of cnc stone cutting machines are the key to preventing safety hazards. It should be ensured that the equipment has sufficient stiffness and stability to withstand various forces and vibrations during processing. At the same time, the equipment should be maintained and inspected regularly to detect and deal with potential problems in a timely manner, such as worn blades, loose bolts, etc.

Improve cnc stone cutting machine operating skills and safety awareness

Operators are a key factor in the stone processing process. They should have rich operating experience and professional skills, and be able to master the operation methods and precautions of cnc stone cutting machines. In addition, safety training should be strengthened to improve the safety awareness of operators and make them fully aware of the seriousness and consequences of safety hazards such as stone fragmentation or falling off.

Adopt cnc stone cutting machine protective measures and emergency plans

During the processing, necessary protective measures should be taken, such as wearing protective glasses, gloves, etc., to reduce the harm to personnel caused by stone fragmentation or falling off. At the same time, an emergency plan is formulated to clarify the emergency measures and rescue procedures that should be taken in the event of a safety accident to ensure that the accident is controlled as soon as possible and losses are reduced.

Implement strict quality management and monitoring

Quality management is an important means to prevent safety hazards such as stone chipping or falling off. A complete quality management system should be established to conduct strict testing and evaluation of raw materials, semi-finished products and finished products. At the same time, advanced monitoring technology is used to conduct real-time monitoring and data analysis of the stone processing process, so as to discover and deal with potential problems in a timely manner.

Strengthen cnc stone cutting machine cooperation and exchanges

Maintain close cooperation and exchanges with other companies and experts in the industry to share each other’s experiences and lessons. Through joint research and discussion, we will continue to improve the safety and efficiency of stone processing.

In short, it is necessary to deal with safety hazards such as stone fragmentation or falling off that may occur in cnc stone cutting machines from many aspects. Through the comprehensive application of measures such as understanding the characteristics of stone, optimizing equipment configuration and maintenance, improving operating skills and safety awareness, taking protective measures and emergency plans, implementing strict quality management and monitoring, and strengthening cooperation and communication, the incidence of safety hazards can be significantly reduced. Ensure the smooth progress of the production process and the safety and health of personnel.