Table of Contents

In today’s construction and decoration industries, stone is highly prized for its unique texture, durability and beauty. However, in order to meet different usage requirements, such as load-bearing and decorative effects, the processing and installation of stone materials have become particularly important. As a key piece of equipment for stone processing, the stone cnc router plays a vital role in designing stone cnc router according to specific needs.

The functions and functions of stone cnc routers

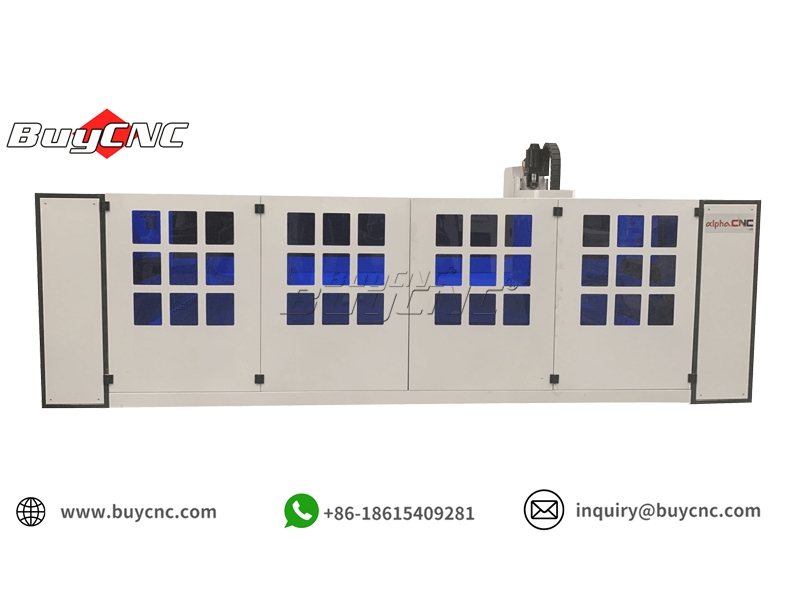

Stone cnc router is a device used for cutting, polishing, engraving and other processing of stone. It uses diamond cutting tools or other carbide cutting tools to perform precise processing on stone through high-speed rotation and movement. The working principle of the stone cnc router is based on advanced CNC technology and mechanical transmission system, which can achieve efficient and precise processing of stone.

Design stone cnc routers according to load-bearing requirements

In terms of load-bearing requirements, the design of stone structures needs to consider the stability and safety of the structure. The stone cnc router can precisely cut and polish the stone according to the design requirements so that it conforms to the size and shape of the load-bearing structure. For example, in load-bearing structures such as bridges and building columns, stone structures need to withstand greater pressure and impact. Therefore, high-hardness stones need to be used and accurately processed and installed by stone cnc routers to ensure the stability of their structures. and security.

Design stone cnc router according to decorative effect

In terms of decorative effects, the design of stone cnc routers needs to consider aesthetics and artistry. The stone cnc router can carve, hollow out and other processing on the stone according to the design requirements, so that it can present various unique textures and patterns. For example, in interior decoration, stone cnc routers can be used to make decorative elements such as background walls, floors, and fireplaces. The textures and patterns processed by stone cnc routers can be coordinated with the indoor environment to create a unique artistic atmosphere.

Stone cnc router design challenges and solutions

When designing stone mechanisms, you may encounter some challenges, such as the hardness of the stone, processing accuracy, installation difficulty, etc. In order to solve these problems, the following measures can be taken:

Choose the right stone: Choose the right stone according to the use needs. For example, the load-bearing structure needs to choose high-hardness stone, and the decorative elements can choose stone with beautiful texture.

Improve processing accuracy: By optimizing the CNC system and tool design of the stone cnc router, the processing accuracy is improved to ensure that the size and shape of the stone mechanism meet the design requirements.

Innovative installation methods: Use innovative installation methods, such as using special connectors and fixing methods, to reduce installation difficulty and improve installation efficiency.

Through precise processing and installation, stone cnc routers can meet different usage requirements such as load-bearing and decorative effects. During the design process, it was necessary to select appropriate stone materials, improve processing accuracy, and innovate installation methods to meet various challenges. In the future, with the continuous advancement of technology and continuous innovation of design, stone cnc routers will be applied and developed in more fields.