Table of Contents

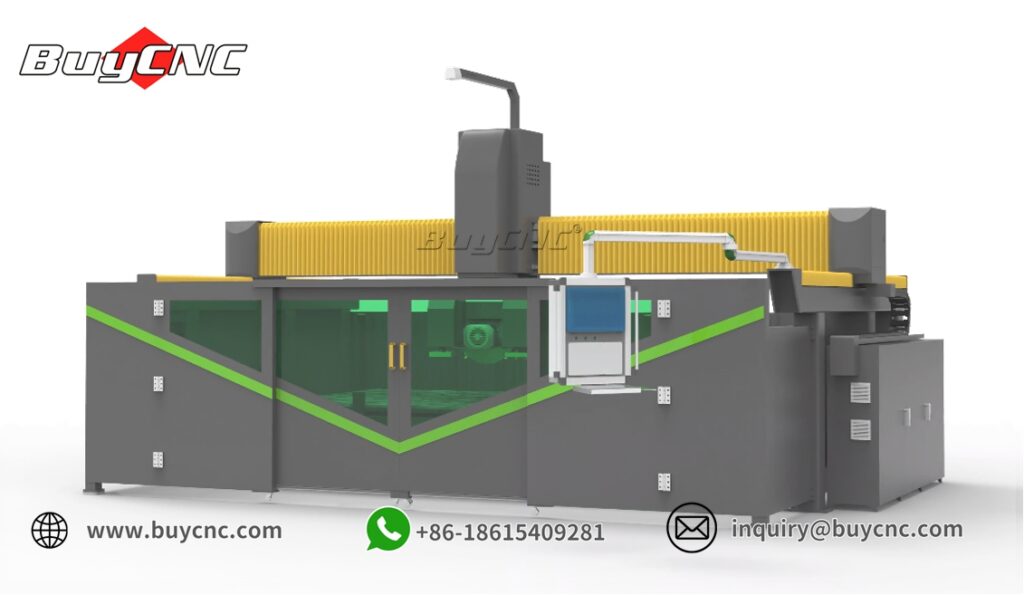

As an important element of architecture and decoration, the design of 3d stone carving machine must not only meet practical requirements, but also take into account aesthetics. How to achieve artistic design while ensuring functionality is a question that every designer needs to consider carefully.

The practicality of 3d stone carving machine design

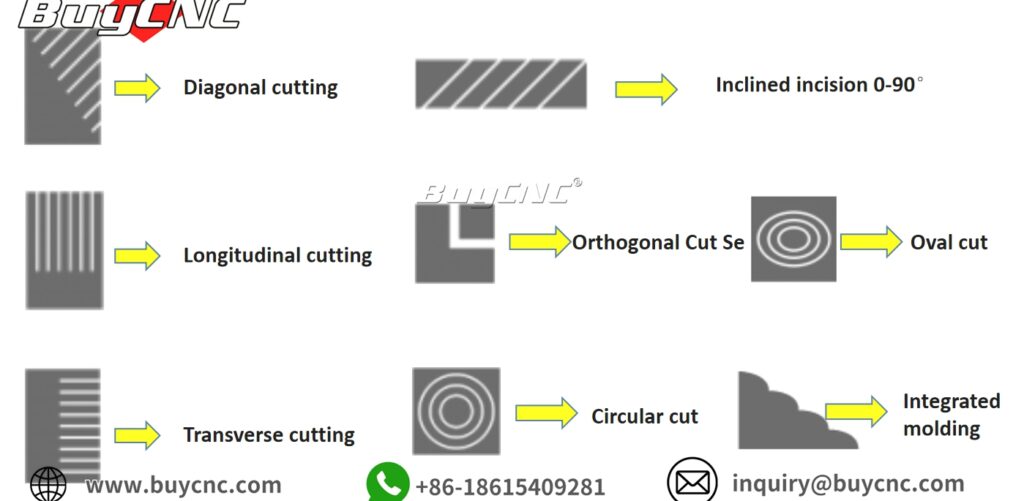

First of all, ensuring the practicality of the design of the 3d stone carving machine is the basis. Designers need to conduct detailed analysis and planning of the use scenarios, load-bearing requirements, opening methods, etc. of 3d stone carving machines. For example, when designing a stone revolving door, factors such as door size, weight, and turning radius need to be considered to ensure that the door opens and closes smoothly. At the same time, designers also need to consider the safety performance of 3d stone carving machine to avoid potential safety hazards such as pinching hands and falling off during use. Practicality is the cornerstone of design. Only by meeting basic functional requirements can aesthetics be further pursued.

The aesthetics of 3d stone carving machine design

Secondly, the aesthetic design needs to pay attention to the coordination between the 3d stone carving machine and the overall environment. As a part of the building, the style, color and material of 3d stone carving machine should be coordinated with the overall environment to create a harmonious and unified effect. Designers can create unique and beautiful 3d stone carving machine by selecting appropriate stone types, colors and textures, and applying modern design techniques and concepts. In addition, detail processing is equally critical, from the smoothness of lines to the rigor of interfaces, all requiring careful polishing by designers. Designers can also consider combining 3d stone carving machine with lighting, greening and other elements to create a more comfortable and pleasant environment.

Details of 3d stone carving machine design

While pursuing aesthetics, designers cannot ignore the details of 3d stone carving machines. Details determine success or failure, and a small oversight may affect the overall aesthetics. Therefore, designers need to carefully design and polish every detail of the 3d stone carving machine, and strive for perfection in terms of the smoothness of the lines, the tightness of the interfaces, and the gloss of the surface.

Finally, in order to ensure that the designed 3d stone carving machine is both beautiful and functional, the designer also needs to work closely with the construction team. Designers need to clearly communicate their design concepts and requirements to the construction team, and conduct real-time supervision and adjustments during the construction process. At the same time, the construction team also needs to have certain professional skills and experience to accurately understand and implement the designer’s intentions to ensure that the final effect of the 3d stone carving machine meets the design requirements.

3d stone carving machine maintenance

However, it is not enough to simply design beautiful and practical 3d stone carving machine. Care and maintenance are equally important. Although 3d stone carving machine are strong and durable, long-term use and the influence of the external environment may still cause problems such as wear and stains. Therefore, regular care and maintenance are essential.

In terms of maintenance, first of all, the 3d stone carving machine should be cleaned regularly. Dust and stains can be removed by gently wiping the surface with a soft cloth and a mild detergent. At the same time, avoid using acidic or alkaline cleaners to avoid damage to the stone. Metal parts on 3d stone carving machines, such as handles, hinges, etc., should also be cleaned and lubricated regularly to ensure their smooth operation.

In terms of maintenance, the stability and safety of 3d stone carving machine should be checked regularly. If problems such as looseness or deformation are found, contact professionals for repairs in time. In addition, the worn parts of the 3d stone carving machine can be properly repaired and renovated to extend its service life.

In addition, in order to avoid unnecessary damage to 3d stone carving machine, we also need to pay special attention in daily use. Avoid using sharp objects to scratch the stone surface, and avoid heavy objects directly hitting 3d stone carving machine, etc.

To sum up, ensuring that the designed 3d stone carving machine is both beautiful and practical requires designers to comprehensively consider and plan in terms of practicality, aesthetics and detail processing. Only by meeting the basic functional requirements, focusing on coordination with the overall environment, and carefully handling every detail, can we create 3d stone carving machine works that are both practical and beautiful.