Do you know 3 axis CNC router machine, 4 axis CNC router machine, and 5 axis CNC router machine? Do you know which machine to choose when you buy the machine? This is an issue that must be considered for every buyer. If you don’t understand, then I will introduce these three kinds of machines for you next.

3 Axis CNC Router Machine:

The 3 axis CNC machine is the most common machine in the CNC machine market today. It has three axes, namely X, Y, and Z axes. In three-axis machining, the workpiece remains stationary, while the cutting tool moves along the three axes to mill the part. It can move left and right on the X axis, move back and forth on the Y axis, and move up and down on the Z axis. So the 3 axis CNC router machine is mainly used for plane cutting and 2D parts production.

The 3 axis CNC machine is suitable for processing a variety of materials, such as wood, metal, plastic, composite materials, etc., and has been widely used in furniture manufacturing, sign carving, metal processing and other fields.

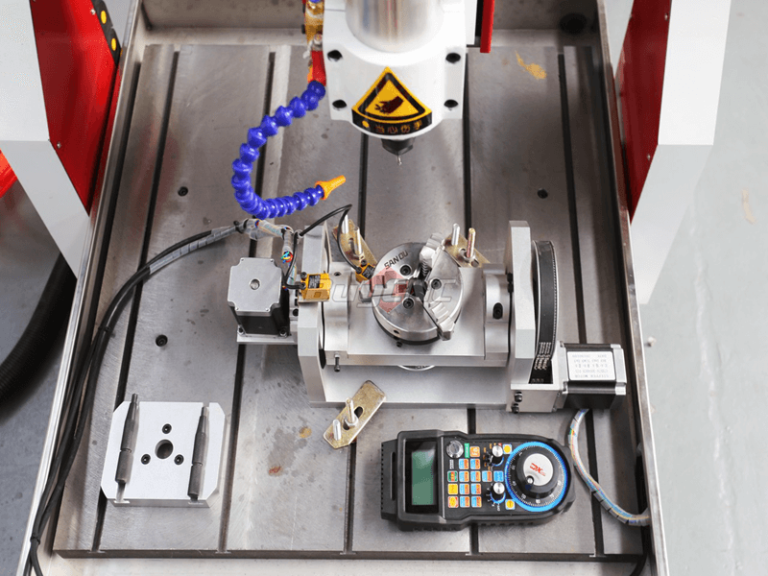

4 Axis CNC Router Machine:

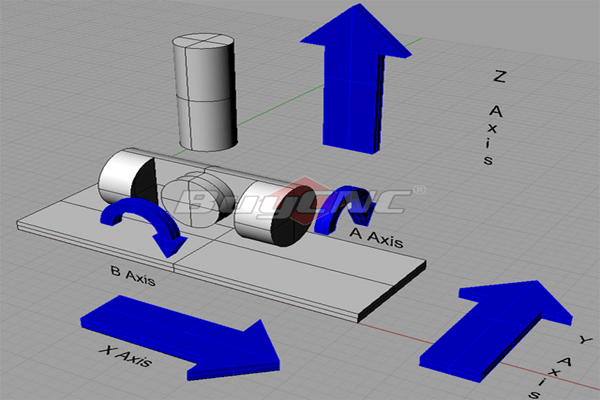

The 4 axis CNC router machine is an upgraded version of the 3 axis CNC router machine. It runs on the X, Y, and Z axis the same as the three axis CNC machine, but it also has an A axis that rotates around the X axis. The A axis is Installed by yourself. As shown in the figure, the X, Y, and Z axes are the three familiar axis, and the A and B axes are potential. We can install the fourth axis at the position of the A axis or the B axis.

In general, the A axis rotates around the X axis of the machine, and the B axis rotates around the Y axis of the machine, but in fact, the fourth axis can be moved, so whether you align the X axis or the Y axis, it will It is the A axis. With this fourth axis, the machine can process materials at multiple angles and can also process three planes of material. So it realizes the 3D processing of circular, curved and cylindrical materials.

The 4 axis CNC router machine can realize the production of three-dimensional products such as statues, and can also complete some plane carving work. Now it has been widely used in keel making, mold making, 3D processing and other industries.

5 Axis CNC Router Machine:

The 5 axis CNC router machine has five axes and it is like an upgraded version of the 4 axis CNC router machine. It has all the axes of the 4 axis CNC machine, and it also has an additional rotation axis (with the X, Y, Z axis and A axis, B axis shown in the figure above). It can process the workpiece on five sides at a time, Thereby greatly improving the cutting accuracy and production efficiency. The 5 axis CNC router machine has two processing methods, namely simultaneous five-axis machining and 3 +2 machining. The second machining method is easier to program, but the frist machining method can improve the quality of the workpiece and extend the life of the tool.

The 5 Axis CNC router machine as a very advanced machine, it is usually used to process solid metal and very complex workpieces.So it is mainly used in heavy industry industries such as automobiles and aerospace. If you want to produce high-precision and difficult workpieces, please choose 5 axis CNC machine.

Buying Advice:

If you are a newbie who just started CNC machine industry and mainly use CNC machine to process flat materials, please choose the cheapest and simplest 3 Axis CNC router machine.

If you are going to use CNC machine for 3D machining and processing some irregular objects, then please choose 4 Axis CNC mill machine.

If you are a CNC engineer with rich work experience and want a powerful CNC machine, then the 5 axis CNC router machine can meet your needs. But if you are not too experienced, but want to buy the 5 axis CNC machine, please purchase it with caution, because its operation is more complicated and programming is more complicated. Maybe you can choose a high-quality 4 axis CNC router machine to replace it.