How To Cut The Foam

What kind of foam can be cut by CNC router

As people’s product quality requirements become higher and higher, many products we buy now use foam to protect the products. Because of its strong plasticity and low cost, foam is very popular.

Foam is now one of the best materials that can be used for engraving because of its light weight and low density, and the flexibility of the foam itself allows it to be made into almost any shape. It is often used to make prototype molds, protect fragile products, etc. Engravable foam is made of a variety of materials, including polyisocyanurate, which is also known as ISO. ISO is a thermosetting material, it can Withstand higher temperatures without melting. It can retain the details of the carving, so it is suitable for creating complex foam products.

Although the strength of ISO carved foam is surprisingly strong, it must be handled with extreme care to avoid damaging the material. The foam is easy to tear, and the worker must be careful not to scratch the foam before carving.

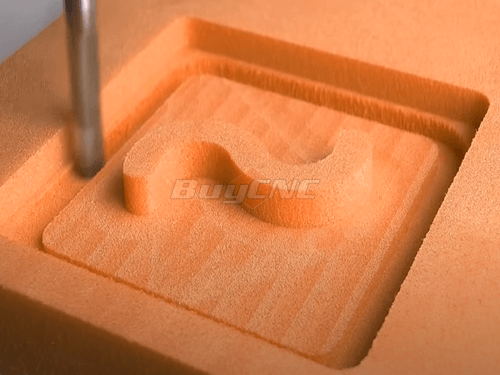

Now, using CNC router machine to cut foam is a very common method, because CNC router can cut grooves of different depths, it can even cut complete 3D contour patterns according to the product style. So that the product can perfectly match the pattern after the foam is cut.Then I will introduce you how to cut foam perfectly.

How to cut foam perfectly

1.Choose the right cutting head:

Because the density and size of foam materials vary greatly, it is very important to know which foam material is suitable for which tool. If you want to cut high density foam and hard foam like Polyurethane (PU), the straight flute bit maybe your best choice. If you want to cut lightweight or soft foam like Polyethylene (PE), then you may need to use a special swing Only the knife can make high-quality and precise cutting. At the same time, what kind of shape you are going to cut with foam is also very important. For example, if you are going to cut 3D deep product contours, you usually use a 5-inch (120mm) vibrating knife to cut.

2.Choose the right cutting bit tools:

In order to obtain a better cutting effect, it is important to choose a correct CNC router bit. For example, if you choose a downward spiral bit, it may cause too much material to be cut or leave a larger pit. If you select an upward spiral router bit, it will raise the material and carve out unwanted contours.For most foam materials, we recommend you to use a twin fluted straight cutter, which has high cutting accuracy, produces less waste, and cuts smoothly.

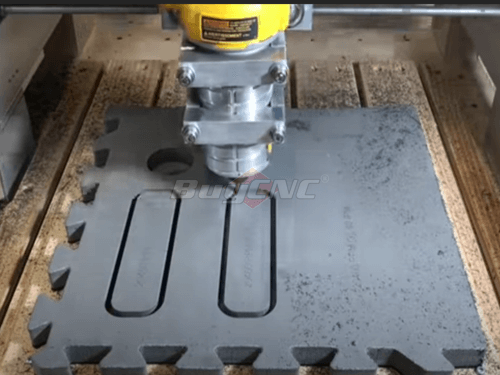

3. Fix the foam material:

For foam materials, how to fix the foam is a more difficult problem, because most of the foam is very light and easily deformed. So those ordinary T-slot workbenches cannot perfectly fix the foam material. Then choosing a CNC router machine with vacuum suction function may be a good way. Of course, there is another way to solve this problem, that is to apply a low-viscosity plastic film on the bottom of the foam material to fix the foam, so that the foam cutting can also work normally.

4. Start carving the foam:

First fix the foam on the worktable, and then import the pattern or contour you want to cut into the CNC router machine. When cutting, you must pay attention to removing waste and keeping the material stable. You can add a small amount of grooves and other details when engraving, so that the product can better match the foam packaging.

The Applicationes of Cutting Foam

Because we can cut foam quickly and perfectly.Now the foam can be used in Logos (3D logos), grids, signs, indoor and outdoor advertising labels, decorative elements, market stalls, store props and displays, POP displays, theater or cinema decorations, model products, various packaging, entertainment, architectural shapes, Large building models, theme props, pipe insulation, precast concrete molds, columns, etc.

BuyCNC provides solutions for the processing of foam materials of various sizes and shapes. We have a number of CNC router machines with high cost performance that can cut foam. If you want to buy a CNC router, we will recommend the most cost-effective CNC router machine for you according to your needs.